NTN Exhibits at “AUTOMOTIVE ENGINEERING EXPOSITION 2021 ONLINE”May 18, 2021

| Date | May 26 (Wed) to July 30 (Fri), 2021 |

|---|---|

| Admission | All visitors are requested to register (for free). |

NTN Corporation (hereafter, NTN) exhibits at “AUTOMOTIVE ENGINEERING EXPOSITION 2021 ONLINE” from May 26 to July 30.

NTN will exhibit products with the theme of “Future Technologies Made by NTN.” As technologies for responding to CASE and creating future vehicles with safety, secure, and comfort, we will introduce products that respond to trends in automotive market such as electrification, low fuel consumption, and higher efficiency, with videos and photographs.

As introduction of products, we will exhibit the “Low Friction Hub Bearing III,” which reduces friction by 62% compared to the conventional product and new products which will be exhibited for the first time. In addition, we will introduce products under two themes: “New NTN Products Helping to Advance EV/HEV” and “NTN's Core Technologies Supporting EV/HEV.” As “New NTN Products Helping to Advance EV/HEV,” we will exhibit products such as “Creepless Bearing” which stops progressive wave type creep by applying undercut machining on the outer diameter of the outer ring of a bearing, which is the industry first way and “Low Temperature Rise and Low Torque Tapered Roller Bearing” which contributes to more efficient differentials with the world's highest level in low temperature rise and low torque. As “NTN's Core Technologies Supporting EV/HEV,” we will introduce products such as “Ultra-low Friction Sealed Ball Bearing” which realizes both low torque and long operating life as bearings for transmissions and gearboxes.

Additionally, two videos will be available: videos of “sHUB,” Hub Bearing with Steering Assist Function and “Products for Electrification.” “sHUB” is a product that combines hub bearings with a mechanism that adjustments for steering angle of wheels, and we will introduce features of improved “sHUB.” The video of the “Products for Electrification” shows the four products that contribute to the electrification of various automotive applications such as oil pumps and shifts, such as the “Electric Motor and Actuator” and the “Mechanical Clutch Unit (MCU) for Next-generation Steering” in detail.

Main exhibits

“Ra-sHUB” Hub Bearings with Steering Function for Rear Wheels

New Product

This is a module product of front wheel hub bearings that modifies the hub bearing “sHUB*” with steering assist function that incorporates a mechanism that adjusts the steering angle. It is compact and can be applied on a variety of vehicles with any type of rear-wheel suspension just like conventional hub bearings and realize rear-wheel steering in vehicles of all suspension types. It improves the cornering performance of the vehicle and the stability when going straight at high speeds. It also contributes to improving fuel efficiency by reducing tire running resistance.

Press Release

Press Release on May 28, 2021: Development of “Ra-sHUB” Hub Bearings with Steering Function for Rear Wheels

https://www.ntnglobal.com/en/news/new_products/news202100047.html

* Press Release on May 23, 2018: Development of “sHUB,” Hub Bearing with Steering Assist Function

https://www.ntnglobal.com/en/news/new_products/news201800053.html

“Small and Lightweight CVJ for Rear of Sub-axle”

New Product

This is a CVJ that realizes the world's highest level in small and lightweight for the driven wheels (sub-axles) of FF-based 4WD vehicles. In 2015, we developed “Lightweight Driveshaft for FR vehicle*” for FR vehicles and FR-based 4WD vehicles which adopted the concept of dedicated design that limits operating angle required for rear CVJ. We applied this concept to CVJ for FF-based 4WD vehicles. By reviewing maximum operating angles and adopting thin and small components with optimized designs, we developed small size and lightweight CVJs while maintaining the required strength.

Press Release

Press Release on May 26, 2021: Development of “Small and Lightweight CVJ for Rear of Sub-axle”

https://www.ntnglobal.com/en/news/new_products/news202100044.html

* Press Release on October 28, 2015: Development of “Lightweight Driveshaft for FR vehicle”

https://www.ntnglobal.com/en/news/new_products/news201500074.html

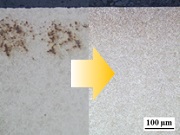

“Hydrogen Embrittlement Resistant Bearings”

New Product

This product realizes three times more long operating life than our standard type bearings, against bearing failure in early stage due to hydrogen combining new steel and special heat treatment technology. New steel limits hydrogen atoms and even when hydrogen atoms are generated, it suppress the speed of hydrogen atoms penetrating (diffusion) into the bearing. Furthermore, by introducing a nitriding and quenching process in the special heat treatment process, it is possible to achieve long operating life under conditions where foreign object is contaminated. For new steels, we have selected components that reduce CO2 emissions during heat treatment process to reduce environmental impact.

Press Release

Press Release on May 25, 2021: Development of “Hydrogen Embrittlement Resistant Bearings”

https://www.ntnglobal.com/en/news/new_products/news202100043.html

Needle Roller and Cage Assembly for Planetary Gear

New Product

This is a needle roller and cage assembly for planetary gear with high speed rotation performance, long operating life, more quietness for planetary gears used in automotive automatic transmissions (AT). “Welded cage with carburized steel” improves fatigue strength to enhance high speed rotation performance by approximately 10% compared to conventional product. The roundness “New crowning roller for high load” is enhanced to lower noise level by approximately 8% compared to conventional product, meeting the needs of EV that requires more quietness. Additionally, optimizing crowning shape suppresses improves surface initiated damage life under severe lubricating conditions.

Press Release

Press Release on May 26, 2021: Development of Needle Roller and Cage Assembly for Planetary Gear

https://www.ntnglobal.com/en/news/new_products/news202100045.html

Creepless Bearing

It stops progressive wave type creep* by applying undercut machining on the outer diameter of the outer ring of a bearing, which is industry first way. While there has been a growing demand for more compact and lightweight motors and transmissions, bearing raceways and housings used in these drive units tend to be a thin section type. It leads to creep which causes abnormal noises or vibrations in the apparatus or shorten the operating life of the bearing. This product can stop creeping by replacing standard type bearings of the same dimensions with no additional components.

* Phenomenon in which the distortion of the outer ring caused by a load acting on a rolling element becomes a progressive wave and the outer ring turns and slips in the same direction as the rotation of inner ring.

Press Release

April 21, 2021: Development of “Creepless Bearing” for Automobiles

https://www.ntnglobal.com/en/news/new_products/news202100032.html

“Low Temperature Rise and Low Torque Tapered Roller Bearing”

By adopting the newly developed plastic cage and optimizing the internal bearing design, it improves low temperature rise (capacity for protection against seizing) by 10 times and reduces rotational torque by 66%. While the amount of oil used in transmissions and differential gears decreases, and the oil is switched to lower viscosity oil, it adapts to severe lubrication condition due to such changes as well as further torque reduction.

“Low Friction Hub Bearing III”

A hub bearing (a component that supports rotation of tires) reducing rotational friction by 62% and improving vehicle fuel efficiency by approximately 0.53% compared to the conventional product. By improving ingredient and viscosity of grease, applying seal structure with labyrinth, and optimizing the preload inside the bearing, the product reduces the rotational friction of the bearing itself with maintaining the performance. Additionally, it can prevent the fretting wear* in low-temperature condition.

* Wear caused by micro-vibration during transportation of vehicles

“Ultra-low Friction Sealed Ball Bearing”

It achieves 80% rotational torque reduction when compared to conventional products through adoption of newly developed seals which arranges arc-shaped micro convexes at regular intervals on the sliding contact section of the seal lip. The torque is the same level as that of bearings without seals. During rotation, the seal is floated slightly due to the wedge film effect of the micro convexes, resulting in the rotation torque reduction. As the convexes are micro, the seal prevents hazardous foreign matter from entering into the bearing to ensure bearing operating life.

Products for Electrification

We will show four products that adapt to electrification such as “Electric Motor and Actuator” and the “Mechanical Clutch Unit (MCU) for Next-generation Steering” with a video. These products contribute to the electrification of various automotive applications with smooth and precise control realized by core technologies NTN has developed ever.