Development of “Creepless Bearing” for Automobiles

(New name:“CreepLess Bearing” for Automobiles*)April 21, 2021

* The name of this product was changed to the name of “CreepLess Bearing” for Automobiles

from March 2022.

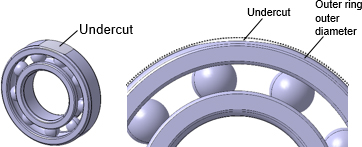

Stops creeping by applying undercut on outer diameter of the outer ring in an industry first!

NTN Corporation (hereafter, NTN) has developed a “Creepless Bearing” that actually stops creeping by applying our proprietary undercut machining on the outer diameter of the outer ring of a bearing.

In recent years, there has been a growing demand for more compact and lightweight motors and transmissions for automobiles including EVs and HEVs to achieve more fuel and electricity efficiency. Therefore, bearing raceways and housings used in these drive units tend to be a thin section type, resulting in these deformations potentially causing a phenomenon called “creep,” in which the fixed outer ring rotates and slips circumferentially. There are several types of creep depending on the direction of rotation and phenomena. In particular, in bearings in which a heavy load*1 is applied within the transmission in a specific direction, a progressive wave type creep*2 often occurs. In this phenomenon, when the rigidity of the outer ring or the housing is insufficient, the outer ring rotates circumferentially due to a distortion of the outer ring, which should not move. If this phenomenon occurs, the misalignment or inclination of the shaft increases due to wear between the fitting surfaces of the outer ring and the housing. This may cause abnormal noises or vibrations in the apparatus, or shorten the operating life of the bearing due to wear contaminants.

The developed “Creepless Bearing” is a product that has succeeded in stopping the progressive wave type creep generated by the distortion of the outer ring with an entirely different method from the conventional measures for the creep.

The “Creepless Bearing” was designed to avoid contact with the housing by providing an undercut part on a part of the outer diameter of the outer ring. This design blocks the progressive wave of distortions and stops the progressive wave type creep*3 under conditions where load is applied from a specific direction. The “Creepless Bearing” is easy to assemble and can replace standard type bearings of the same dimensions as no additional components are required.

As EVs and HEVs become increasingly popular in the future and automotive components become smaller and lighter, there will be a growing need for creep-resistant bearings. In addition to this product, NTN offers a lineup of products to address this need, including the “Expansion Compensation Deep Groove Ball Bearing*4,” “AC Bearing *4,” and “CreepGuard Bearing*5,” which can prevent creeping and creep wear.

NTN will contribute to the electrification, electricity efficiency, and fuel efficiency of automobiles through the development and supply of products that meet the need for more compact and lightweight motors and transmissions.

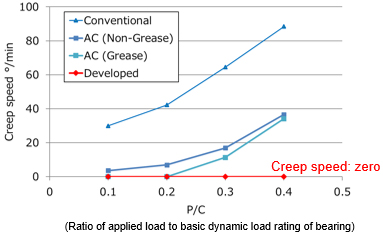

- When load is 10% or more of the dynamic load rating of the bearing

- A phenomenon in which the distortion of the outer ring caused by a load acting on a rolling element becomes a progressive wave and the outer ring turns and slips in the same direction as the rotation of inner ring.

NTN TECHNICAL REVIEW No.81 (2013) “A Creep Mechanism of Rolling Bearings”

https://www.ntnglobal.com/en/products/review/pdf/NTN_TR81_en.pdf - In an NTN assessment test, creep stopped within one rotation of the outer ring.

- NTN “Ball and Roller Bearings Catalog” in CAT.No.2203/E

- Bearings with NTN's proprietary solid lubricating coating on the outer diameter of the outer ring can reduce the volume of creep wear by more than 90% compared with standard type bearings.

Features

| 1. Creep speed | Zero (in an NTN assessment test, creep stopped within one rotation) |

|---|---|

| 2. Excellent assemblability | Same installation dimension as standard type deep groove ball bearing (interchangeable) |

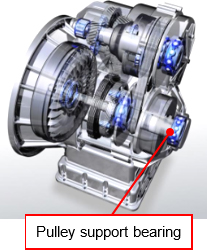

Application

Deep groove ball bearings for automotive transmissions and EV/HEV motors

Inquiries about this release

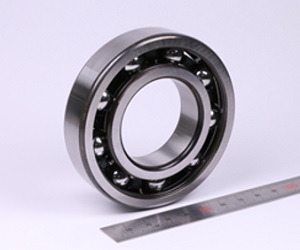

Product photo

Creepless bearing

Creepless bearing

Product structure

Outer diameter is not a perfect circle

Creep speed test

Application Site

CVT transmission

CVT transmission