Development of “Hydrogen Embrittlement Resistant Bearings”May 25, 2021

Preventing failure of bearings in early stage due to hydrogen by integrating new steel and special heat treatment technology

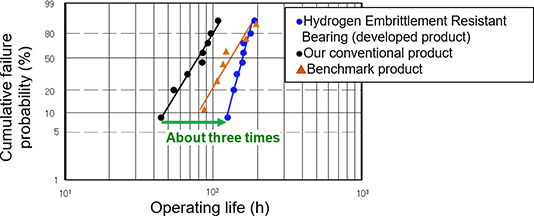

NTN Corporation (hereafter, NTN) has developed “Hydrogen Embrittlement Resistant Bearings”, which has three times more long operating life than our standard type bearings, against bearing failure in early stage due to hydrogen combining new steel and special heat treatment technology.

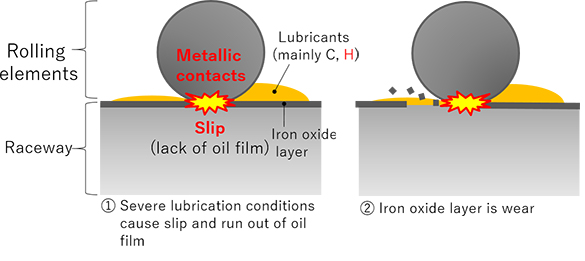

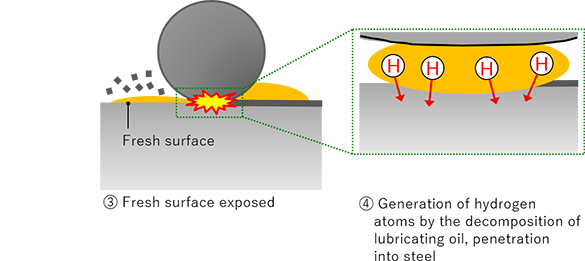

In automotive sector, we are responding CASE, the major challenge that is said to be a revolution once every 100 years. Against the background of electrification in the market, further higher efficiency of power transmission equipment is required. Also, bearings are required to comply with increasingly severe lubricating conditions, such as a reduction in the amount of lubricating oil in the equipment and the use of low-viscosity oil. Bearings may be damaged in early stage under unprecedented severe operating conditions. The reason has been considered to be a hydrogen embrittlement, where hydrogen atoms penetrate into the steel and the strength of the steel decreases, and countermeasures are required.

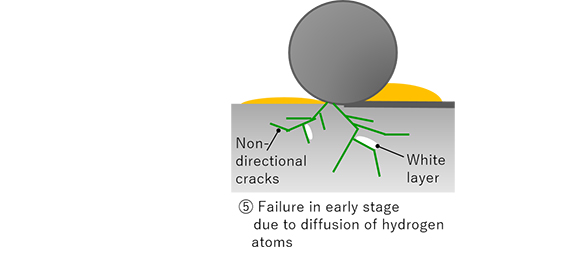

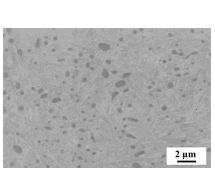

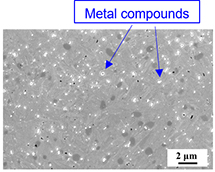

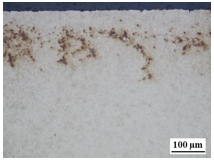

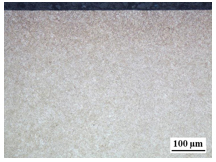

Newly developed “Hydrogen Embrittlement Resistant Bearing” uses a new steel and newly developed special heat treatment technology. This bearing prevents the failure in early stage due to the hydrogen embrittlement and realizes longer operating life. A large number of hard and fine metal compounds are dispersed on the surface of the bearing raceway made of new steel, which make it difficult to make wear even in metal contacts under lean lubrication conditions, thereby limiting the exposure of fresh surface of metal *1, which are the source of hydrogen atoms. In addition, even when hydrogen atoms are generated, the fine metal compounds suppress the speed of hydrogen atoms penetrating (diffusion) into the bearing. Consequently, we have succeeded in improving the life of the developed product by more than three times*2 compared to our standard type bearings. Furthermore, the quenching process in the special heat treatment process improves the resistance to foreign objects by introducing a nitriding and quenching process that increases the nitrogen concentration of bearing raceway, which makes it difficult for the product to undergo fatigue. This makes it possible to achieve long operating life under conditions where foreign object is contaminated.

For new steels, we have selected components that reduce CO2 emissions during heat treatment process to reduce environmental impact.

NTN will globally propose this developed product to contribute to further improvements in reliability such as automobiles and industrial machinery.

The developed product will be exhibited for reference in “Automotive Engineering Exposition 2021” (online), which will be held from May 26 to July 30.

- Surface from which a very thin layer of iron oxide on the metal surface is removed

- In rapid acceleration/deceleration operation conditions containing a large amount of water in the lubricating oil

Features

| Long operating life | More than three times longer operating life compared to standard type bearings |

|---|---|

| Improvement of foreign matter resistance | Nitriding treatment to increase the nitrogen concentration of bearing raceway surface during quenching improves the operating life under conditions of contaminated lubrications. |

Application

Generally used in Automobiles and industrial machinery

Mechanism of hydrogen atoms penetration to the steel and failure in early stage

|

|

|

Comparison of our standard type and the developed product

| NTN standard type bearings | Developed product | |

|---|---|---|

| Raceway surface Surface photo |

|

|

| Raceway Cross-sectional photo * After hydrogen embrittlement test |

44 hours passed

44 hours passed(failure in early stage occured) |

107 hours passed

107 hours passed(No failure) |

Result of hydrogen embrittlement operating life