NTN Exhibits at 15th Shanghai International Automobile Industry Exhibition “Auto Shanghai 2013”April 17, 2013

| Date | April 20 (Sat) to 29 (Mon), 2013 |

|---|---|

| Venue | Shanghai New International Expo Center, Shanghai, China |

| NTN Booth | N4/D101 |

NTN will run an exhibit at the 15th Shanghai International Automobile Industry Exhibition “Auto Shanghai 2013” with the theme “Creating and advancing environmental technologies”.

In addition to the “Module Concept Drive-By-Wire EV” test vehicle developed by Shanghai Jiao Tong University (China) that is equipped with NTN's EV system products, a range of products and systems for next-generation vehicles such as EV and eco-friendly vehicles will be on display. The two-seater, four-wheel electric commuter concept model “Q'mo” will also demonstrate its “pivot turn” and “lateral move” driving capabilities.

We look forward to seeing you at the event.

Main exhibits

In-Wheel Motor System Concept “Q'mo”

The “In-Wheel Motor System Concept” consisting of a steering system using the compact steering actuator and the in-wheel motor system for electric commuters developed by NTN will be on show.

The In-Wheel Motor System was recognized with the Innovation Award at “Automechanika2012” and the Grand Prix of Mechatronics Award at the “European Mechatronics Meeting (EMM) 2012”.

The two-seater, four-wheel electric commuter concept model “Q'mo” will be test driven at the event to demonstrate its functionality and features. Check out the enjoyment and convenience that the In-Wheel Motor System can provide compact EVs, including “pivot turn” and “lateral move”.

Hub Joint with Incorporated Advanced Sensor Technology

Features a “wide-range, high-resolution small sensor” capable of detecting vehicle movements of 1 mm, and a “multi axis load sensor” that reduces the detection response time from the tires down to 1/5th that of other sensors. NTN's proprietary “press-cut spline method” has been adopted for the joint between the hub bearing and CVJ, in what is the world's first corner module product equipped with two integrated sensors.

Press Cut Spline Hub Joint

A joint that helps to reduce weight drastically and deliver higher performance with a new joint method developed based on NTN's high technical capabilities as a manufacturer of both hub bearings and CVJs. The newly developed product can be used on automobile manufacturer assembly lines without having to change the current 3rd generation hub bearing and CVJ assembly process in use today.

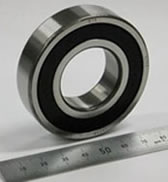

High Speed and Low Torque Deep Groove Ball Bearing for EV/HEV

A ball bearing that uses a “Low Torque Plastic Retainers Capable of High Speeds” to maintain reliable, low torque operation at high speeds with oil lubrication, capable of DN up to 1.2 million. The use of a shield shape on the side of the retainer limits the quantity of grease flowing into the bearing to drastically reduce stirring resistance. The internal design of the bearing has also been optimized to reduce rolling viscosity resistance, which helps to reduce torque by 50% or more compared to conventional products.

Low Torque Sealed Deep Groove Ball Bearing for EV motor

This bearing delivers a 50% reduction in rotational torque compared to conventional products, and is designed for applications such as EV motors and auxiliary electric drive motors. The use of a low-torque cage serves to reduce grease stirring resistance, allowing the use of low-torque grease with low viscosity and outstanding heat-resistance.

Low-torque Strut Bearing for Severe Environments

Features a seal for use in severe environments, including protection against penetration of muddy water, and a proprietary low-torque labyrinth structure. The floating seal reduces the penetration of water into the bearing by 90% compared to conventional structures, and torque is reduced by 50% compared to bearings from other manufacturers.