Development of “Low Torque Sealed Deep Groove Ball Bearing” contributing to higher efficiency in EV motorsFebruary 20, 2012

[Newly developed grease and cage reduce rotational torque by 50% or more]

NTN Corporation (hereafter, NTN) has developed the “Low Torque Sealed Deep Groove Ball Bearing”, which contributes to higher efficiency of motors installed within electric vehicles (EV) and other applications.

Various efforts to reduce the power used by EV drive motors have been implemented in recent years as a means of reducing the weight of required batteries and to extend the mileage of vehicles. To help achieve these efforts, bearings used in EV motors require an even lower level of torque.

Since sealed deep groove ball bearings used as support bearings in EV motors operate at light loads and high speeds, the rotational torque largely depends on the characteristics of grease within the bearing.

The newly developed “Low Torque Sealed Deep Groove Ball Bearing” is designed with a new type of grease developed to reduce stirring resistance, which is the main cause of rotational torque. The newly developed grease consists of a base oil with a low-viscosity, and contains a thickener with a fine, microscopic molecular structure. This thickener improves the retaining strength of the base oil, which reduces the quantity of thickener required.

Sound levels (sound performance) have been kept at the same level or lower than conventional motor grease. The formula of grease additives has also been reviewed and optimized to limit the effects of oxidation at high temperatures, and deliver a longer operating life over conventional products.

In addition to development of the grease, a low-torque cage has been utilized to address the contact shape between the rolling element and cage pocket, which helps to limit the amount of excess grease on the bearing rolling surface.

NTN plans to market the “Low Torque Sealed Deep Groove Ball Bearing” globally for a variety of uses, including EV motors, automotive electrical instruments and auxiliary devices, other types of motors used in industrial machinery.

Features : Compared with conventional products (standard sealed deep groove ball bearings)

| (1) Torque |

50% or more reduction |

|---|---|

| (2) Sound |

same level or lower |

| (3) Operating life |

same or better under actual operating conditions |

Inquiries about this release

Product Photo

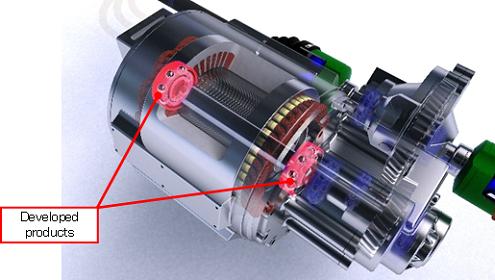

“Low Torque Sealed Deep Groove Ball Bearing”

Applicable Parts

EV motor and applicable parts of developed products (example layout)