NTN Starts Proposal of High Efficiency/Shudderless Driveshaft for EVsMay 23, 2024

- Driveshaft combining optimal constant velocity joints (CVJs) for EVs

- The world's highest level in transmission efficiency and shudderless to extend cruising distance and improve ride comfort

NTN Corporation (hereafter, NTN) has started proposals of driveshafts that achieve the world's highest level in transmission efficiency and shudderless by combining High Efficiency Fixed Type CVJ “CFJ” with shudderless Sliding Type CVJ “PTJ” to electric vehicles (EVs). We will propose this product to EVs that require higher transmission efficiency and NVH (noise, vibrations, and harshness) to contribute to the extension of cruising distance and improvement of ride comfort.

High Efficiency Fixed Type CVJ “CFJ”

High Efficiency Fixed Type CVJ “CFJ”

Shudderless Sliding Type CVJ “PTJ”

Shudderless Sliding Type CVJ “PTJ”

Construction of High Efficiency/Shudderless Driveshaft

Construction of High Efficiency/Shudderless Driveshaft

Driveshaft is a component that transmits the power (torque) of a motor or other powertrain unit to a tire. It consists of a fixed type CVJ on the tire side, a sliding type CVJ on the powertrain side, and a shaft that connects these CVJs.

In recent years, EVs have been increasingly developing and spreading. In order to extend cruising distance, efforts have been made to reduce electricity consumption. However, when the operating angle of driveshaft increases because of mounting a large battery or changing the layout of the drive unit with the aim of securing the interior space, torque loss ratio tends to increase. Therefore, a reduction in torque loss ratio is required even for a high operating angle. In addition, the replacement of power source with motors has led to further quietness of automobiles, and the need to improve NVH of driveshaft is increasing.

High Efficiency/Shudderless Driveshaft

In response to these needs, NTN proposes a driveshaft that combines High Efficiency Fixed Type CVJ “CFJ” with Shudderless Sliding Type CVJ “PTJ” as an optimal driveshaft for EVs. “CFJ” is a CVJ that features low torque loss ratio (higher transmission efficiency) and “PTJ” features reducing sliding resistance that leads to vibrations. These performances are the world's highest level. Combining them extends the cruising distance and meet the specific requirements of low vibration and quietness of EVs.

When replacing the conventional product with a driveshaft that combines “CFJ” with “PTJ,” it is able to reduce the torque loss ratio by 70% or more and improve the electricity consumption by 3.19%*1, 2. Also, the CO2 emission can be reduced by 1.71 g/km for engine vehicles*1, 3.

We have already proposed High Efficiency/Shudderless Driveshaft and started mass-production for SUVs. We are currently receiving a large number of inquiries regarding EVs and hybrid electric vehicles (HEVs). NTN will accelerate proposal of this product as well as the Compact Lightweight Rear Driveshaft “R Series*4” and “E Series” featuring compactness and lightweight globally as a driveshaft that contributes to extending cruising distance and improving ride comfort for vehicles such as EVs and HEVs.

NTN will exhibit this product at the “Automotive Engineering Exposition 2024 YOKOHAMA” to be held in Pacifico Yokohama from May 22 to 24.

- Comparison with conventional product using “EBJ” for fixed type CVJ and “EDJ” for slicing type CVJ

- Assumption of a vehicle with weight of 1,500 kg and electrical efficiency of 155 Wh/km testing under WLTP conditions (CVJ operating angle: 9°)

- Assumption of a vehicle with weight of 1,500 kg and fuel efficiency of 17.6 km/L testing under WLTP conditions (CVJ operating angle: 9°)

- Press release on May 11, 2023:

NTN Expands Sales of Compact Lightweight Rear Driveshaft “R Series”

https://www.ntnglobal.com/en/news/new_products/news202300032.html

High Efficiency Fixed Type CVJ “CFJ”

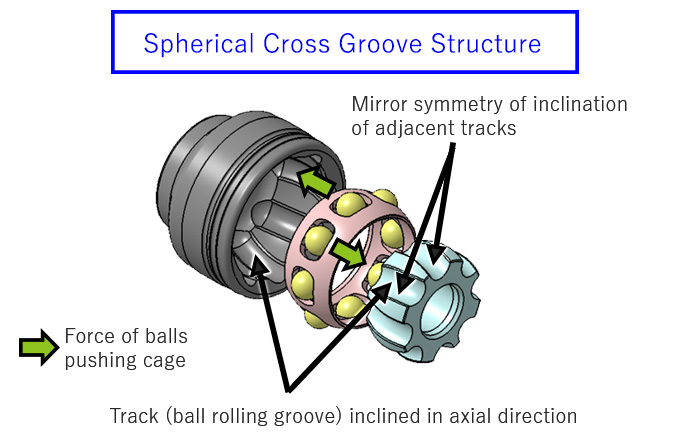

“CFJ” is a fixed type CVJ that greatly changes the conventional basic structure and adopts NTN's proprietary “Spherical Cross Groove Structure*5” that offsets the forces involved in internal components. Torque loss ratio can be reduced by 50% or more in compared to conventional product and torque loss ratio can be significantly reduced even at high operating angle. Its world's highest level in transmission efficiency is evaluated by automotive manufactures around the world and it has been adopted by many automobiles.*6

- Structure where the spherical ball raceway grooves through which balls pass intersect each other on inner ring and outer ring. Adjacent raceway grooves are inclined with each other to distribute directions of forces from balls alternately and cancel them.

- Press release on November 7, 2022:

NTN Receives Mass-production Order of High Efficiency Fixed Type CVJ “CFJ”

https://www.ntnglobal.com/en/news/new_products/news202200069.html

Shudderless Sliding Type CVJ “PTJ”

“PTJ” is a sliding type CVJ that adopts NTN's proprietary “Pillow Journal Structure” that suppresses the tilt of roller cassettes of inside components even when operating angle becomes high. It features the world's highest level in shudderless and reduces sliding resistances, which leads to vibrations, by 50% or less compared to the conventional product. It is adopted by many vehicles such as luxury cars that emphasize quietness and SUVs with high operating angle.

Construction of High Efficiency Fixed Type CVJ “CFJ”

The axial load acting on the balls is generated in opposite directions on adjacent tracks (ball rolling grooves) to offset the axial load between each part and reduce internal frictional force.

Construction of Shudderless Sliding Type CVJ “PTJ”

The roller cassette can roll on the outer race track without tilting. In addition, by placing needle rollers inside the roller cassette, the rolling itself is smoothed and the internal frictional force is reduced.