NTN Receives Mass-production Order of High Efficiency Fixed Type CVJ “CFJ”November 7, 2022

Contribute to improvement in fuel/electricity efficiency of automobiles through the world's highest level of efficiency during transmitting torque

NTN Corporation (hereafter, NTN) receives mass-production order for High Efficiency Fixed Type CVJ “CFJ*1” with the world's highest level of efficiency from several automotive manufacturers. While maintaining the fundamental characteristics of the fixed type CVJ “EBJ” with the world's best level of compactness and lightweight, ”CFJ” can reduce torque loss ratio by more than 50%.

Toward realizing a carbon-free society, the automotive industry has been accelerating its efforts to improve fuel and electricity consumption in order to reduce CO2 emissions. Accompanied with this trend, constant velocity joints (CVJs), components of driveshafts that convey the power (torque) from powertrain unit such as engines or motors to tires, are increasingly required to achieve higher efficiency.

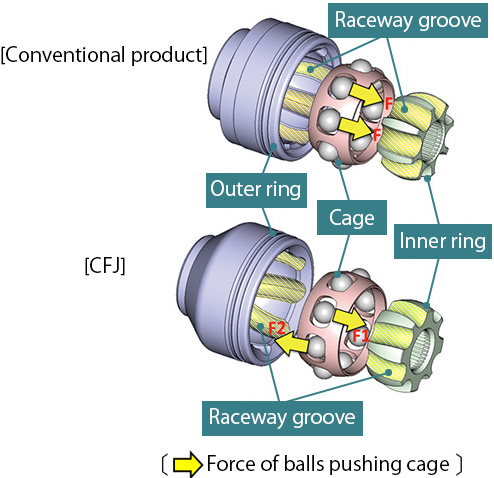

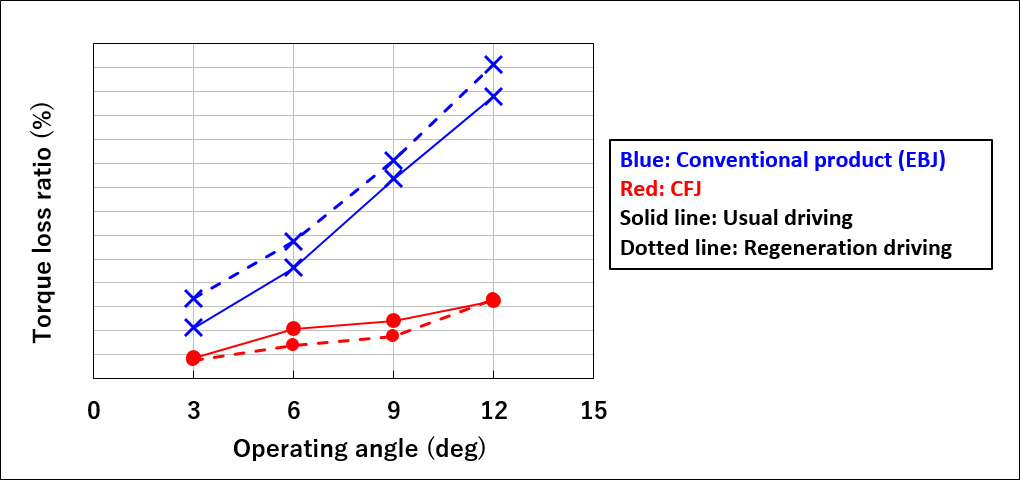

When CVJs transmit torque, balls as the internal component push the cage in one direction, causing friction between components and generating torque loss. Additionally, as operating angle of CVJs increases, the force of balls pushing the cage also increases and it leads increase of torque loss ratio. “CFJ” can reduce torque loss ratio by more than 50% compared to the conventional product by adopting NTN's proprietary “Spherical Cross Groove Structure*2” where the adjacent tracks (raceway grooves) are inclined with each other to distribute directions alternately of forces from adjacent balls pushing the cage. In addition, even if the operating angle of CVJ increases, the proprietary structure can significantly suppress the increase in torque loss ratio.

In addition to the high-efficiency of “CFJ,” the reduction in torque loss ratio at large operating angles were highly evaluated from customers, resulting in mass-production orders this time.

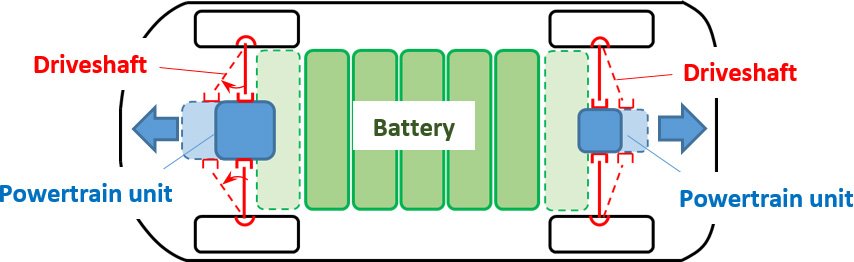

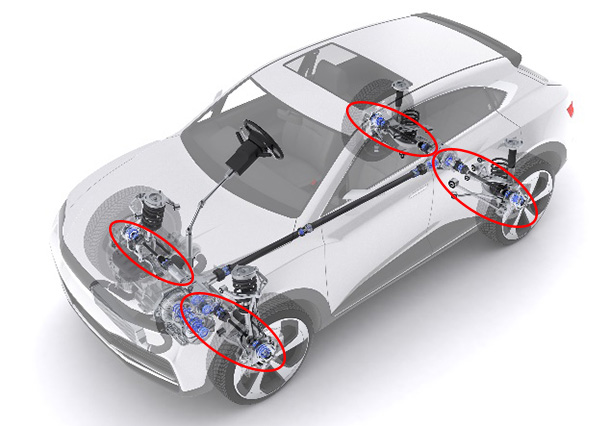

“CFJ” is an optimal product for SUVs that are popular globally in recent years and for EVs/HEVs that are increasingly spread as well. In EVs, operating angle of CVJ is increased, as the powertrain unit tends to be mounted at the end of vehicles, taking into account the installation of large-capacity batteries, expansion of the room space, and crash safety. “CFJ” contributes to improvement in both flexibility of vehicle layout and saving electricity as it demonstrates high-efficiency even at large operating angle. EVs and HEVs are equipped with regeneration brake systems to generate and store electricity by motor when the vehicle slows down. The proprietary structure of “CFJ” also can reduce torque loss ratio when transmitting regeneration torque to opposite direction of usual driving, so it improves regeneration efficiency.

In the case*3 where fuel efficiency of internal combustion engine vehicles by replacing EBJ with CFJ is calculated based on JAPIA LCI calculation guideline*4, it is expected that the efficiency is improved by 0.62% and CO2 emissions are reduced by 0.96g/km. While CO2 emission regulations become stricter, the high environmental performance of “CFJ” is also highly evaluated from automotive manufacturers.

As a top manufacturer of driveshafts, NTN will continue to develop and provide high performance products including “CFJ,” of which NTN receives orders of mass-production this time, to lead the automotive industry and contribute to reduction in environmental load through reducing fuel efficiency and electricity of automobiles.

-

Press release on May 10, 2012:

Development of High Efficiency Fixed Type CVJ “CFJ”

https://www.ntnglobal.com/en/news/new_products/news201200039.html - Structure where the spherical ball raceway grooves through which balls pass intersect each other on inner ring and outer ring. Adjacent raceway grooves are inclined with each other to distribute directions of forces from balls alternately and cancel them.

- Assumption of a vehicle with weight of 1467kg and fuel efficiency of 17.6km/L testing under WLTP conditions (CVJ mounting angle: 9°)

- Calculation method for efficient life cycle environmental load in manufacturing and use of automobiles stipulated by Japan Auto Parts Industries Association (JAPIA)

Features (compared to conventional product (EBJ))

| High-efficiency | 50% reduction in torque loss ratio compared to the conventional product (world's highest level) |

|---|---|

| Lightweight and compactness | Equivalent to the conventional product (world's best level) |

| Operating angle | Equivalent to the conventional product (up to 47°) |

Product photo

Applied area

Structural comparison with conventional product (EBJ)

Efficiency Characteristics at High operating angle

- CFJ can reduce torque loss ratio by more than 50% compared to EBJ

- CFJ's torque loss ratio is less affected by angle increase

- Torque loss ratio of CFJ in regeneration driving is as less as that in usual driving

EV vehicle layout

- In EV, powertrain unit tends to be mounted at the end of the vehicle considering installation of large-capacity batteries, expansion of the room space, and crash safety, and the mounting angle of driveshaft (CVJ operating angle) tends to become large.