NTN Expands Sales of Compact Lightweight Rear Driveshaft “R Series”May 11, 2023

World's best level of compactness and lightweight

High evaluation for fuel efficiency improvement

NTN Corporation (hereafter, NTN) expands sales of Compact Lightweight Rear Driveshaft “R Series”. The product is suitable for rear-wheel drive models that is widely adopted in luxury vehicles. While each automotive component is becoming more compact and lightweight toward saving fuel efficiency and electricity, the product has been highly evaluated for its fuel efficiency, leading to adoption in vehicles such as SUVs and EVs with rear-wheel drive of automotive manufactures in Japan, Europe and etc.

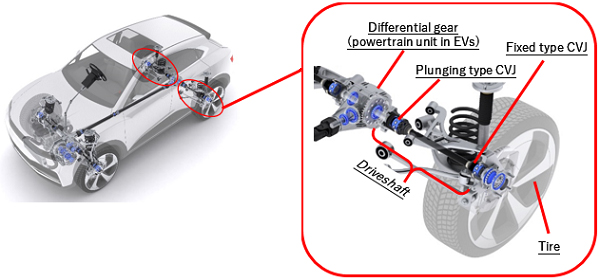

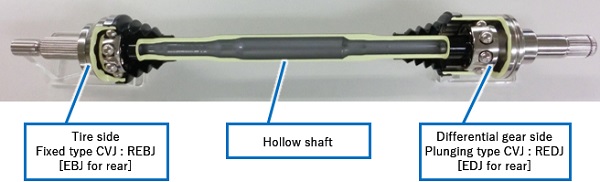

A driveshaft is a component that transmits the power (torque) of powertrain units such as engines and motors to tires. It consists of two constant velocity joints (CVJs), one on the tire side (fixed type) and the other on the differential gear side (plunging type), and a shaft that connects them. Compact Lightweight Rear Driveshaft “R Series” offers a wide range of size variations based on the design of “Lightweight Driveshaft for FR vehicle*1” which NTN developed in 2015, and is applicable to internal combustion vehicles and electric vehicles (EVs) with rear-wheel drive.

Conventionally, CVJs for front have been used in driveshaft for rear. “R Series” is optimized for shapes that are limited to operating angle and functions required for rear, and adopts thinner hollow shaft and compact boots. By reviewing these components, it achieves the world's best level of compactness and lightweight as rear CVJs with 30% reduction in weight and 3 to 5% reduction in outer ring outer diameter compared to the conventional product achieving the world's best level in compactness and lightweight as CVJs for front.

While automotive industry has been taking measures to reduce CO2 emissions toward achieving decarbonized society, the need for lightweight driveshaft is growing more than ever. When fuel efficiency by adopting “R Series” to internal combustion vehicles is estimated*2 based on JAPIA LCI calculation guideline*3, the fuel efficiency is expected to improve by 0.05% and the CO2 emission is expected to reduce 0.075g/km compared to vehicle with the conventional product. Automotive manufactures around the world including Europe highly evaluated the high environmental performance and adopted the product. NTN has been steadily expanding sales of the product since its mass-production in 2018.

In the future, as fuel efficiency regulations become more stringent, the product is expected to be adopted in luxury vehicles, where rear-wheel drive models tend to be adopted. As to EVs, the number of four-wheel drive vehicles (4WD) in which powertrain units are installed in both front and rear of vehicle is increasing in order to improve driving performance. Considering these situations, the demand for the product featuring its lightweight is expected to increase even further.

As a leading manufacturer of driveshafts with the second largest global market share, NTN will lead the industry by developing and providing products that steadily capture automotive trends and changing needs. Additionally, NTN will contribute to reducing environmental impact by further expanding sales of this series and other high performance products.

-

Press release on October 28, 2015:

Development of “Lightweight Driveshaft for FR vehicle”

https://www.ntnglobal.com/en/news/new_products/news201500074.html - Assumption of a vehicle with weight of 1467kg and fuel efficiency of 17.6km/L testing under WLTP conditions (CVJ mounting angle: 6°)

- Calculation method for efficient life cycle environmental load in manufacturing and use of automobiles stipulated by Japan Auto Parts Industries Association (JAPIA)

Features of “R Series”

| Lightweight | 30% reduction compared to the conventional product (Driveshaft applicable to medium-sized rear-wheel drive vehicles: 2.2kg weight reduction) |

|---|---|

| Compactness | 3 to 5% reduction in outer ring diameter compared to the conventional product |

| Operating angle | 19 degrees (fixed type and plunging type) |

Structure of “R Series”

Applied area