NTN Exhibits at the 29th Japan International Machine Tool Fair “JIMTOF2018”October 19, 2018

| Date | November 1 (Thu) to 6 (Tue), 2018 |

|---|---|

| Venue | Tokyo Big Sight |

| Booth No. | W2051 |

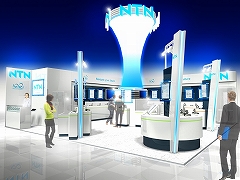

NTN will run a booth at the 29th Japan International Machine Tool Fair “JIMTOF2018”, with the theme “Navigate your future - NTN ULTAGE -.” Exhibits will include the ULTAGE* series of precision rolling bearings for machine tools as well as other products and technology for machine tools.

The booth will feature details of the High-speed Angular Contact Ball Bearing with Outer Ring Refueling Hole that allows refueling direct from the outer ring to help reduce consumption of lubricant and compressed air and also allows machine tools to be made more compact. A broad range of proprietary technologies will also be on display, including the first public exhibits of “Sensor Integrated Bearing Unit” for Machine Tool Spindles and Machine Tool Spindle Bearing with Air Cooling Spacer for Grease Lubrication.

Other exhibits will include products related to robotics sensing technology, CMS technology and bearings for robots as technology and products designed to support the recent trend in “machine tool and robot coordination.” Dynamic exhibits will also demonstrate how smoothly the “i-WRIST” wrist module moves like a human wrist, as well as the Multi Track Magnetic Ring used in areas such as robot joints.

We look forward to seeing you at the event.

* ULTAGE is the name for NTN's goal of achieving the ultimate performance with precision bearings, and expresses the “Ultimate” performance on any type of “Stage.”

Main exhibits

|

Reference exhibition product “Sensor Integrated Bearing Unit” for Machine Tool SpindlesBy using sensing around the bearing raceway surface, this product can prevent seizure together with advanced condition monitoring in machine tool main spindles. Preventing seizure before it occurs reduces the man-hours and cost involved in procuring parts and replacing the main spindle when the main spindle on a machine tool has seized. It also decreases the time until the machine tool can resume operation and provides an improvement in productivity and reduces costs. Furthermore, it contributes to an improvement in reliability because regular maintenance can be performed more accurately. |

|

|

Reference exhibition product Machine Tool Spindle Bearing with Air Cooling Spacer for Grease LubricationApplying NTN’s proprietary air-cooling technology, this product has an increased high-speed rotational performance and rigidity of 10%. This means that grease lubricated bearings, which are beneficial from cost and environmental perspectives, can be used in machining centers, complex processing units and other high-speed equipment where air-oil lubrication is conventionally required. |

|

|

Reference exhibition product Angular Contact Ball Bearing for High-Speed and Heavy-Cutting Machine ToolsThis product has a high-speed rotational performance of dmn value* of 1.6 million as well as 1.3 times the load capacity and allowable axial load compared to NTN's conventional products. This enables a single machine tool to cover the rough machining work and finishing processes that previously required numerous machine tools, and also helps to further increase productivity of machining centers, turning machines and complex processing units. * An indicator that expresses the rotational performance of bearings and is bearing pitch circle diameter (mm) x rotational speed (min-1) |

|

|

ULTAGE Series of Precision Roller Bearings for Machine ToolsPrecision bearings that support high efficiency processing, high reliability, high quality processing and environment-conscious design required for machine tools. Demonstrates excellent ability due to such factors as the adoption of seals on both sides, special grease, special material/surface modification and also the optimization made to the internal bearing design. |

|

|

High-speed Angular Contact Ball Bearing with Outer Ring Refueling HoleImplementing a lubrication hole directly on the outer ring eliminates the need for a lubrication mechanism in the bearing spacer, which contributes to greater lubrication reliability and a more compact main shaft. Optimal design of the outer ring oil groove and lubrication hole, as well as O-rings installed on either side of the lubrication hole prevent oil leaking from the bearing outer diameter surface. |

|

“i-WRIST” Wrist Joint ModuleThe use of a proprietary link mechanism means the module is compact, space-efficient and covers a wide range of operating angles. Minor changes in positions (angles) can be made at high-speeds like human hands, which perpendicular multi-joint robots and pan-tilt mechanisms* have difficulty with. This means the module can operate as a substitute for appearance inspections of complex shapes or semi-spherical surfaces that are performed by humans. * Mechanism that enables panning in the horizontal plane (left/right directions), as well as tilting in the vertical plane (up/down directions). |

|

Multi Track Magnetic RingA ring-shaped product developed mainly to detect the angles of robot joints. It can output data on absolute angles when combined with the dedicated sensor. More environmentally friendly that optical types, its thin, lightweight design helps to make devices more compact. It also has a hollow shape that is large enough to pass cables through the internal diameter, making it suitable for use in robot joints. |

|