Development of “Angular Contact Ball Bearing for High-Speed and Heavy-Cutting Machine Tools”October 29, 2018

Development of ULTAGE Series*1 for both high-speed rotational performance and load resistance

NTN Corporation (hereafter, NTN) has developed the “Angular Contact Ball Bearing for High-Speed and Heavy-Cutting Machine Tools” with a high-speed rotational performance of dmn value*21.6 million as well as approximately 1.3 times the load capacity and allowable axial load compared to NTN's conventional products. This enables a single machine tool to cover the rough machining work and finishing processes that previously required numerous machine tools, and also helps to further increase productivity of machining centers, turning machines and multi-function machines.

Demand is growing in recent years for machine tools capable of a range of machining work in a single unit, from heavy-duty cutting at low to medium speeds that requires load resistance as well as finishing work at high rotating speeds. Heavy-duty cutting machine tools need high-speed rotational performance that exceeds the current dmn value of 1.2 million to be capable of finishing work, whereas a high load resistance is required for finishing work machine tools to allow heavy-duty cutting. This has led to a greater need for bearings for spindles with an increased level of both high-speed rotational performance and load resistance, which have a trade-off relationship.

The newly developed “Angular Contact Ball Bearing for High-Speed and Heavy-Cutting Machine Tools” features optimized internal bearing design such as a larger ball diameter and increased retainer strength to achieve a high-speed rotational performance dmn value of 1.6 million, as well as approximately 1.3 times higher load capacity and allowable axial load compared to conventional products. This allows the bearings to be used under the tough condition of greater high-speed rotation and high load combination to help increase machine tool productivity, and also achieve a stronger spindle capable of withstanding impacts with tools and machined pieces.

NTN will exhibit the developed product at “The 29th Japan International Machine Tool Fair (JIMTOF2018)” to be held at Tokyo Big Sight from November 1 to 6, and will propose it to various machine tool manufacturers and spindle manufacturers.

- ULTAGE is the name for NTN's goal of achieving the ultimate performance with precision bearings, and expresses the “Ultimate” performance on any type of “Stage.”

- The dmn value represents bearing rotational performance. dmn value = dm (bearing pitch circle diameter, mm) × n (rotational speed, min-1)

Features

| 1. High-speed rotational performance | dmn value 1.6 million (when used with air-oil lubrication, ceramic balls) |

|---|---|

| 2. High load capacity allowable axial load | Approximately 30% improvement compared to NTN's conventional product (HSE type) |

Applications

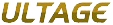

Machine tool spindles (machining centers, lathes, multi-function machines)

Inquiries about this release

Product photo and position where product is used

Example of boundary dimensions: φ70 × φ110 × 20 mm

Structure

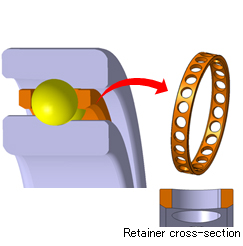

Conventional product (HSE type)

Conventional product (HSE type)

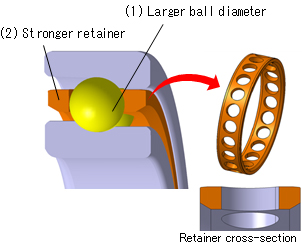

Angular Contact Ball Bearing for High-Speed and Heavy-Cutting Machine Tools

Angular Contact Ball Bearing for High-Speed and Heavy-Cutting Machine Tools

- Optimized internal bearing design such as larger ball diameter

- Stronger retainer with larger cross-sectional area than conventional product (more than 2 times cross-sectional area)