NTN Enhances Product Lineup of Bearings Resistant to Electrical Pitting for EVsMay 23, 2024

- Developing conductive bearing using rubber seals with excellent conductivity

- Enhancing product lineup that effectively adapts to electrical pitting caused by two types of current (circulating current and EDM current)

NTN Corporation (hereafter, NTN) has developed a conductive bearing designed for e-Axles, a key component in electric vehicles (EVs). It mitigates electrical pitting due to EDM*1 current by adopting rubber seals with excellent conductivity. Alongside our existing range of insulated products designed to prevent electrical pitting caused by the circulating current in the motor, we have expanded our portfolio with bearings resistant to electrical pitting, a common issue in e-Axle bearings. This will enhance the performance and utilization of e-Axles, contributing to the advancement of EV technology.

- Abbreviation for Electrostatic Discharge Machining

Conductive bearing

Conductive bearing

Example of applications in parallel axis e-Axle (marked in red)

Example of applications in parallel axis e-Axle (marked in red)

Electrical pitting

Electrical pitting, a form of damage that occurs when an electric current passes through a bearing, results in the generation of sparks and the melting of the metal structure, leading to fluting and other forms of damage. Therefore, bearings for motors are required to counteract electrical pitting.

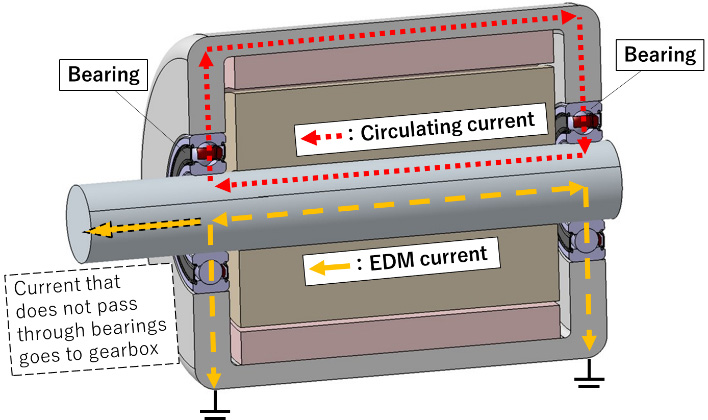

There are two types of current to be addressed by bearings for motors: EDM current passing through the motor shaft, and the circulating current circulating in the motor. The EDM current is generated by voltage variations on the motor shaft during operation, while the circulating current is produced by current leakage into the motor when power is repeatedly turned on and off for inverter control. If these currents are applied to the raceway surface of the bearing, electrical pitting can occur.

To counteract the circulating current, insulated items that suppress the electrification of the raceway surface are effective. However, even with insulated bearings, the EDM current may flow towards the gearbox, potentially damaging the gearbox bearings. Therefore, conductive items are beneficial for directing the EDM current to the motor housing-side.

Conductive bearing

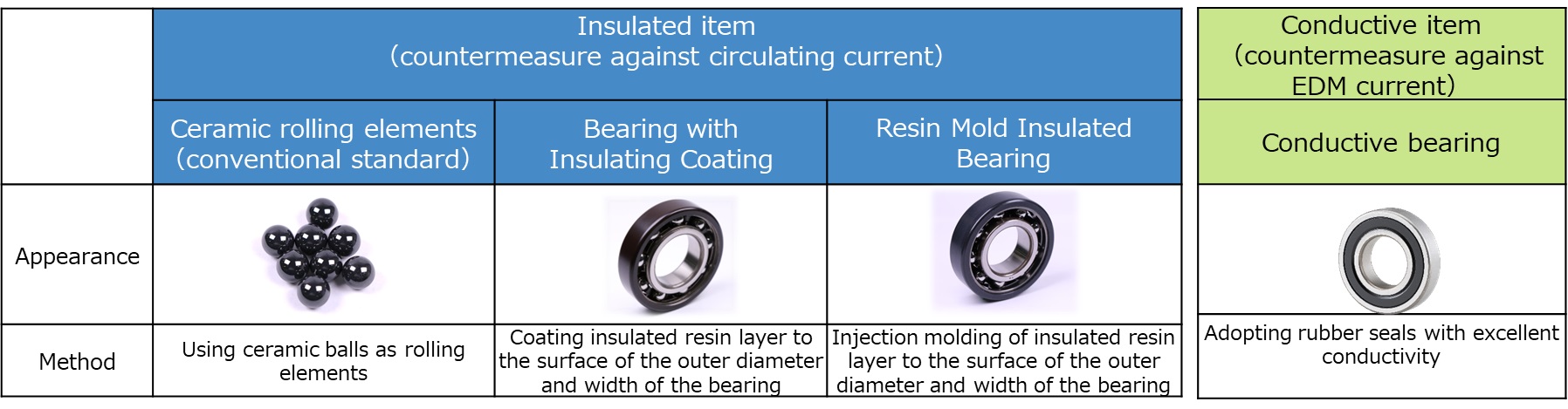

NTN has newly developed a conductive bearing as a countermeasure against EDM currents. This product features rubber seals with excellent conductivity. By allowing current to pass through the rubber seals, the product prevents the occurrence of electrical pitting due to the current passing through the raceway surface. This solution is more space-efficient compared to other countermeasure methods, such as attaching an additional conductive component like a conductive brush to the bearing, as it integrates conductivity to the bearing itself.

NTN has been developing insulated bearings such as ceramic bearings, “Bearing with Insulating Coating*2” where an insulating coating is applied to the bearing's outer diameter and width surface, and “Resin Mold Insulated Bearing*3” that incorporates an injection-molded insulated resin layer onto the bearing's outer diameter and width surface. The development of the conductive item that adapts to EDM current further enhances our ability to address all types of current passing through e-Axle bearings.

- Press release on May 24, 2023:

NTN Develops “Bearing with Insulating Coating” for e-Axle

https://www.ntnglobal.com/en/news/new_products/news202300044.html - Press release on May 23, 2024:

NTN Develops “Resin Mold Insulated Bearing” for e-Axle

https://www.ntnglobal.com/en/news/new_products/news202400044.html

Structure of conductive bearing

Structure of conductive bearing

NTN will globally propose a wide range of bearings resistant to electrical pitting including the conductive bearing to contribute to the further enhancement of performance and use of e-Axles. Furthermore, we will persist in expanding our lineup of bearings resistant to electrical pitting, enabling customers to select the products that best suit their specific usage conditions.

NTN will exhibit our bearings resistant to electrical pitting, including the conductive bearing and the “Resin Mold Insulated Bearing” at the “Automotive Engineering Exposition 2024 YOKOHAMA” held at Pacifico Yokohama from May 22 to 24.