NTN Develops “Bearing with Insulating Coating” for e-AxleMay 24, 2023

- An insulating coating is applied on the surface of the outer diameter and width of the bearing to exhibit excellent insulation performance over 100V

- Suppresses electrical pitting to adapt to the increase in battery voltage in the context of fuel-efficient and energy-efficient vehicles

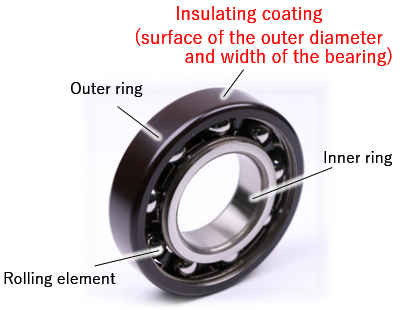

NTN Corporation (hereafter, NTN) has developed a bearing resistant to electrical pitting, “Bearing with Insulating Coating” for e-Axle, used in electric vehicles (EVs) and hybrid electric vehicles (HEVs). Electric current passing through the bearing is suppressed by applying an insulating coating to the surface of the outer diameter and width of the bearing. This bearing has an insulation performance of 100V or higher, and supports the use of high-voltage batteries.

“Bearing with Insulating Coating” for e-Axle

“Bearing with Insulating Coating” for e-Axle

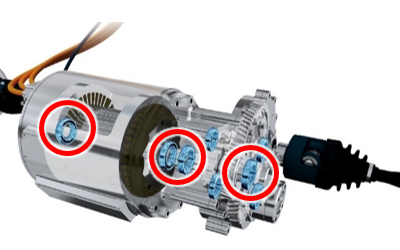

Applied areas in parallel axis e-Axle (red circle)

Applied areas in parallel axis e-Axle (red circle)

Background of Development

In recent years, the automotive market has seen an acceleration in the development and diffusion of environmentally compatible vehicles such as EVs and HEVs, as an effort toward carbon neutrality.

These motor-driven vehicles are equipped with an e-Axle, where the motor, inverter, and transmission are combined into a single unit. The e-Axle is powered by electricity from batteries, and if excess current flows through the bearings, a spark will occur inside the bearings, causing part of the bearing race to melt. This will result in bearing damage such as spalling (flaking). Therefore, it is necessary to address electrical pitting in bearings due to current leakage in e-Axles.

Features

| 1. Electrical pitting resistance |

|---|

| The surface of the outer diameter and width of the bearing is covered with an insulating coating that suppresses current passing through the bearing. This product features insulation performance over 100V. Since the voltage applied to motor bearings is assumed to be less than 10% of the battery voltage, this product can withstand battery voltages up to 800V, which is expected to increase in the future. |

| 2. Heat dissipation |

| The thickness of the coating is designed to provide both resistance to electrical pitting and heat dissipation. The developed product has the same heat dissipation performance as standard products. |

| 3. Wear resistance |

| The insulating coating has a low friction coefficient and excellent wear resistance, enabling an 88% reduction in the total amount of wear on the outer ring outer diameter and housing inner diameter compared to the standard product without the insulating coating. As a result, the product can maintain the coating necessary for insulation even when creeping occurs on the outer ring. |

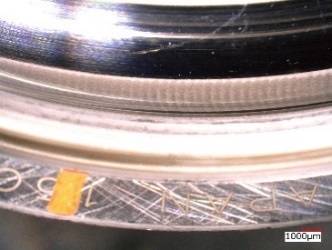

<Raceway surface of outer ring after electrical pitting>

Electrical pitting is seen in standard product

standard product

standard product

developed product

developed product

The developed insulating coating can also be applied to NTN's bearing products for e-Axles including the High Speed Deep Groove Ball Bearing* for EVs and HEVs, which currently has the highest speed rotational performance in the world.

NTN also offers bearings with ceramic rolling elements as products that are resistant to electrical pitting when used in e-Axles. NTN is responding to the increasing demand for electrical pitting resistant products as the e-Axle evolves by adding this cost-effective product to its product lineup of electric pitting resistant products. This will also contribute to the further spread and enhancement of EV and HEV functionality.

NTN will exhibit this product at the “AUTOMOTIVE ENGINEERING EXPOSITION 2023 YOKOHAMA,” held from May 24 to 26 at PACIFICO Yokohama, Japan.

* Press release on May 19, 2022:

NTN Achieves High Speed Rotation Supporting dmn Value of 2.2 Million with Deep Groove Ball Bearings for EVs and HEVs

https://www.ntnglobal.com/en/news/new_products/news202200036.html

Application

e-Axle for EVs and HEVs (motors and gearboxes)

Reference

Electrical pitting of e-Axle

EV batteries are becoming increasingly high in voltage to extend the cruising range of vehicles and shorten battery recharging times. Batteries with approximately 800V are expected to be widely used in the future, and higher voltage will cause more damage to bearings than ever before due to sparks occurring in the bearings. Furthermore, inverter control frequencies are increased to improve the efficiency of motor control, causing the occurrence of electrical pitting to increase, as the number of sparks in bearings increases.

NTN products for e-Axle

e-Axle is becoming increasingly compact and lightweight to increase electricity efficiency in order to extend cruising distance of vehicles. While maintaining its lightweight and compact design, the output power of motors is becoming increasingly higher in order to generate the torque required for driving, and the bearings are required to have high speed rotational performance. Additionally, bearings and their respective housings are becoming thinner to reduce the e-Axle weight, causing creep to occur. Creep is a phenomenon that causes the outer ring of the bearing to rotate in the circumferential direction under load. This will result in misalignment and inclination of the bearing, causing abnormal noise and vibrations, and shortening the life of the bearing due to wear. NTN develops and provides a wide range of products that respond to the unique operating environment of the e-Axle, such as high speed rotation and creep.