NTN Receives Orders for Mass-Production of “Ultra-low Friction Sealed Ball Bearing” for Automotive TransmissionsSeptember 11, 2020

Realize both low torque and long operating life under high speed rotation condition

NTN Corporation (hereafter, NTN) has received orders from several automotive manufacturers for mass-production of the “Ultra-low Friction Sealed Ball Bearing” *1 developed for transmissions of automobiles.

The developed product achieves both low torque and long operating life by adopting a newly designed contact type seal. The rotating torque is reduced to the same level as that of bearings without seals (non-sealed type). The seal prevents hazardous foreign matter from entering the bearing to ensure bearing operating life.

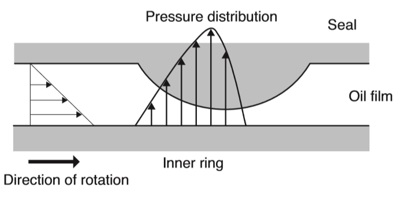

The developed product achieved an 80% rotation torque reduction when compared to conventional products (contact sealed type). The developed seal arranges arc-shaped micro convexes at regular intervals on the sliding contact section of the seal lip. During rotation, the seal is floated slightly due to the wedge film effect*2 of the micro convexes, resulting in the rotation torque reduction.

Additionally, the seal realizes long operating life by preventing foreign matters from entering the bearing, so it can be replaced with a special heat treatment product that has increased the strength of the bearing itself to realize long operating life. After the development in 2017, the product received high reputations from specialized agencies such as receipt of “Mobility Components Award” of “'CHO' MONODZUKURI Innovative Parts and Components Award” sponsored by MONODZUKURI. Nippon. Conference and Nikkan Kogyo Shimbun, Ltd. in 2018*3, and NTN has been continuing proposals of this products for customers. NTN has received orders for mass-production, as customers evaluated the product's features: achievement of to higher functions by simply replacing the conventional product with the developed product as well as the realization of both low torque and long operating life.

This product can be used in vehicles requiring higher speed rotation than ever before such as electric vehicles (EVs) and hybrid electric vehicles (HEVs), that are increasingly being developed, without the risk of seals overheating and damages due to abnormal wear.

As fuel efficiency saving and electrification of automobiles continue to advance, NTN will propose and deploy this product developed by making full use of NTN's tribology, while striving to development of other products that solve customers' issues.

- Press Release: June 5, 2017 “Development of “Ultra-low Friction Sealed Ball Bearing” for automotive transmissions”

https://www.ntnglobal.com/en/news/new_products/news201700050.html - Phenomena of generated fluid pressure when a gap where viscous fluid such as lubricant flows is narrowed

- Press Release: October 2, 2018 “NTN Receives 2018 “CHO” MONODZUKURI Innovative Parts and Components Award, Mobility Components Award”

https://www.ntnglobal.com/en/news/press/news201800091.html

Features

| 1. | Rotation torque: 80% reduction (compared to conventional products (contact sealed type)) |

|---|---|

| 2. | Bearing life under lubrication with foreign matter: 5 times or more (compared to conventional products (non-sealed type)) |

| 3. | Seal circumferential speed: 50 m/s or more (equivalent to more than dmn value*4 1.03 million, compared to conventional products (contact sealed type) 2 times or more) |

- dmn value: An indicator that expresses the rotational performance of bearings and is bearing pitch circle diameter (mm) × rotational speed (min-1)

Inquiries about this release

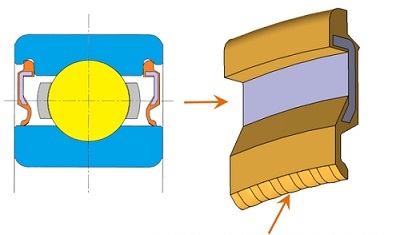

Product Photo

|

Cross-sectional view of the developed product |

Arc-shaped micro convexes arranged on the developed seal (5 locations in the image) |

Wedge film effect slightly floats seals

Wedge film effect slightly floats seals

and significantly reduces drag torque