NTN Receives 2018 “CHO” MONODZUKURI Innovative Parts and Components Award, Mobility Components AwardOctober 2, 2018

NTN Corporation has received the Mobility Components Award at the 2018 “CHO” MONODZUKURI Innovative Parts and Components Award sponsored by MONODZUKURI. Nippon. Conference and Nikkan Kogyo Shimbun, Ltd.

Awarded Product

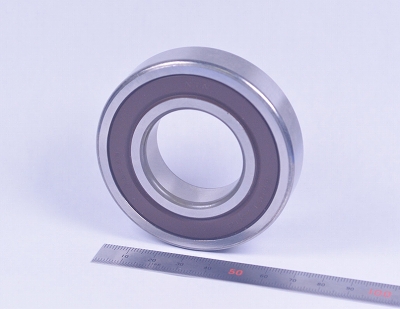

Ultra-low Friction Sealed Ball Bearing

Product Overview

A bearing for transmissions that reduces rotation torque by 80% compared to conventional contact sealed type products by adopting a proprietary shaped ultra-low friction seal. There was an issue that drag torque occurred during rotation due to seal contact for conventional products. However, this product uses a contact seal arranged with arc-shaped (half-cylindrical shaped) micro convexes at regular intervals on the sliding contact section of the seal lip. This prevents harmful hard foreign matter from entering the bearing while it also achieves a low torque effect equivalent to a non-contact sealed type. It also improves seal circumferential speed enabling it to be used for applications that require high speed rotational performance such as EV and HEV.

This product has the following features.

| 1) Rotation torque | 80% reduction (compared to NTN conventional products (contact sealed type)) |

|---|---|

| 2) Bearing life under lubrication with foreign matter | 5 times or more (compared to NTN conventional products (non-sealed type)) |

| 3) Seal circumferential speed | 50 m/s or more (compared to NTN conventional products (contact sealed type) 2 times or more) |

Ultra-low Friction Sealed Ball Bearing

Ultra-low Friction Sealed Ball Bearing

Reason for Receiving the Award

Using a very simple method, a seal was developed with a proprietary shape that reduces rotation torque to the same level as open type bearings while being a sealed bearing. Furthermore, it is excellent for mass-production using the same molding method as conventional seals. It is also expected to be adopted on a larger scale in the market in the near future and contributes to achieving a low-carbon society. These factors led to it winning this year's award.

New Product Release

https://www.ntnglobal.com/en/news/new_products/news201700050.html