Expand Bearing Failure Detection ServiceMay 26, 2020

Start sales of “NTN PORTABLE VIBROSCOPE” detecting bearing abnormalities

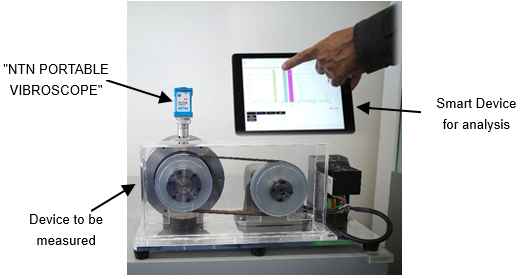

NTN Corporation (hereafter, NTN) has started selling “NTN PORTABLE VIBROSCOPE” in May 2020. This product is compact, hand-held, and easy to carry and set. It enables to do easily advanced bearing diagnostics and is useful for periodic checking of rotating machinery.

This product needs only 7 seconds for measure and analyze and can be handled easily by four installation methods (simple installation with a magnet, secure mounting by screwing, etc.) that match each machine and circumstance to be measured. Also, the product can analyze the OA*1 and FFT*2 at the same time with a single measurement.

In addition, we also begin services that provide diagnostic and analytical reports using this product, and will expand comprehensive technical services to improve the maintainability of facilities.

Expand technical services to meet market needs

Besides selling the product, we also plan to provide services that meet customer needs, such as diagnostic and analytical reports using the product. Technical services will also be expanded, such as holding technical workshops specializing in measuring machine vibrations and diagnostic.

Until now, facility maintenance has relied on the experience and senses of skilled workers, but in recent years, the accumulation of know-how has become difficult due to shortages of human resources and other factors, and there has been an increasing need for tools to detect machine abnormalities. In addition, as customers are becoming increasingly aware of preventive maintenance, the need for condition monitoring is expanding in not only production lines, but also equipment such as conveyance and hydraulic/pneumatic equipment. Our customers also request us to provide not only bearings, but also comprehensive technical services, including the know-how regarding preventive maintenance.

To meet these needs, we have developed and sold “Handy Type Failure Detection Device” *3 in 2014, which is capable of collecting, analyzing and displaying vibration data.

Subsequently, we developed the “NTN PORTABLE VIBROSCOPE,” *4 in 2018 with the aim of downsizing and enhancing functionality. As we conducted a large number of trials in the marketplace, we have further improved our analytical functions and begun sales of this product with enhanced usability.

Taking the opportunity of the sales, NTN will further expand its technological services in response to preventive maintenance. Also we will expand its service and solution business that contributes to extending the life cycle of machinery and equipment and improving productivity using our sensing and digital technologies.

- OA: “Over All”, a method to calculate RMS values, peaks, etc. using the entire vibration waveform.

- FFT: Method to analyze the frequency spectrum of the input vibration signal using “Fast Fourier Transform”.

- Development of “Handy Type Failure Detection Device”: February 2014

https://www.ntnglobal.com/en/news/new_products/news201400009.html - Development of “Handy Type Failure Detection Device II” in November 2018

https://www.ntnglobal.com/en/news/new_products/news201800109.html

Applications

Electric machinery (elevators, pumps, conveying machinery), paper-making machinery, plant equipment, maintenance of machine tools and general industrial machinery facilities, shipping inspection, the tool for the person who provide technical support

Inquiries about this release

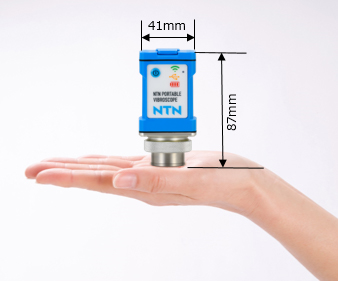

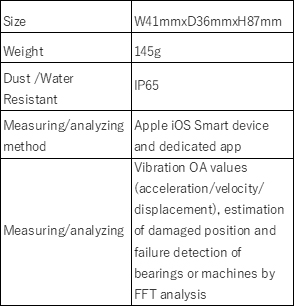

Product Specifications

Usage example

Main points of improvement compared to the conventional product

- Optimize the analysis program that reduces the measurement and analysis time by about half (from about 15 seconds to about 7 seconds).

- Select installation options from four methods, such as direct fastening with magnets or screws

- Change the OS of smart devices for analysis from Android to iOS

- Compact body integrated with vibration pickup, battery box, and connecting cable.

- Conforming to IP65.