Commercialization of High-current “Amorphous Core”June 28, 2012

[High-current core with a high level of design flexibility with injection molding]

NTN Corporation (hereafter, NTN) has created a product line-up of the “Amorphous Core” that can be used at high currents by using injection molding of magnetic material comprising of a mixture of amorphous*1 powder and resin.

The core of reactors*2 and choke coils*3 are generally made by press molding magnetic ferrite*4. In recent years however, reactors installed in storage devices of electric vehicles (EVs), hybrid vehicles (HEVs) and solar power generators, and choke coils used in advanced medical equipment have required greater reliability under increasingly harsh conditions, including higher currents and faster drive frequencies, which has meant that conventional cores made of ferrite have become unsuitable.

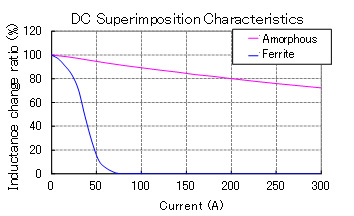

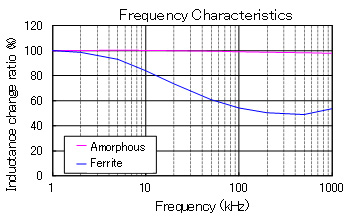

The “Amorphous Core” has been developed by NTN group company Nippon Kagaku Yakin*5 and delivers an inductance*6 reduction ratio of just 30% under high current conditions with DC (direct current) superimposition characteristics*7. This high-reliability core shows no reduction in inductance at high frequency bands of 1000 kHz, and it is capable of reducing electrical signal noise at a high level of efficiency.

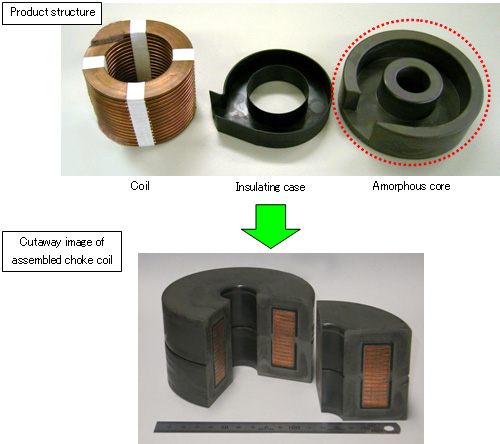

The core can also be made with injection molding, which increases its design flexibility to meet the needs of coils with a greater variety of shapes and larger sizes. The coil is compact at approximately 1/8th the volume of conventional ferrite choke coils, which gives devices a more compact and lightweight design.

“Amorphous Cores” are already being used in some applications, however will be continued to be marketed globally to suit various other applications as one of the leading line-ups in NTN's composite material product business.

*1: A state of matter where atoms and molecules are arranged in a random order.

*2: A passive element that utilizes coils (the element that consumes, stores and releases the supplied electrical power), and which is installed in AC (alternating current) circuits on the input or output side of inverters.

*3: One type of electronic component that limits the flow of high-frequency electric current.

*4: An oxide composite material with iron oxide as one of the main constituents, and used in magnetic materials.

*5: Joined the NTN group in September 2011. Develops composite materials such as sintered alloys and engineering plastics, and possesses a high level of technology for metallic molds and molding processes.

*6: The ratio between the magnetic flux flowing through a circuit and the current causing that magnetic flux. Also called the induction coefficient and inductor.

*7: The change in characteristic values when a current is applied.

Features

- High current, fast drive frequencies

→ Magnetic material made of amorphous powder and resin, delivering low loss under high currents and high frequency bands - High level of core design flexibility

→ Injection molding using a proprietary resin ratio for coils with a greater variety of shapes and larger sizes - Compact and lightweight

→ Approximately 1/8th the volume of ferrite coils (in choke coil applications)

Applications

Reactors for power generation equipment of EV, HEV and solar power, and choke coils for storage devices and medical equipment

Inquiries about this release

Product photo : Choke coil application

Magnetic characteristics