Development of “Sintered Alloy” Manufacturing Technology to the Highest Level in the WorldMarch 27, 2012

[Allows machinery components manufactured with cutting processes to be replaced with sintered alloy]

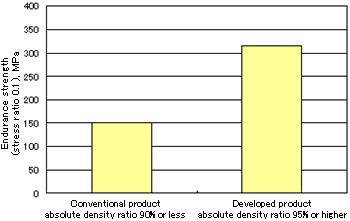

NTN Corporation (hereafter, NTN) has developed the world's highest standard*1 manufacturing technology for “sintered alloy”, capable of manufacturing alloy with an absolute density ratio of 95% or higher, and endurance strength*2 of 300 MPa*3 or higher (maximum stress 700 MPa). This allows drivetrain components such as gears that require precision and durability, which had been manufactured with cutting processes until now, to be replaced with sintered alloy.

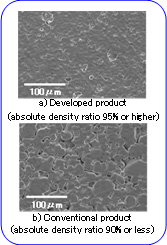

The powder-metallurgy process*4 is one manufacturing method that is available to reduce waste of materials and energy consumption while manufacturing mechanical components as a means of addressing recent environmental and energy issues. Yet as this process involves compressing metal powder together, micropores can easily develop inside the components, resulting in a decrease in fatigue characteristics compared to components manufactured using cutting process of solid metals. The use of sintered alloys in drivetrain components that require excellent fatigue characteristics had been limited due to this reason.

NTN has made improvements to the powder material, and forming and sintering conditions to manufacture high-density sintered compact with an absolute density of ratio 95% or higher, using a relatively low casting pressure of 6 to 10 ton/cm2. The combination with NTN's proprietary heat treatment technology results in an endurance strength of 300 MPa or higher under single press, single sintering process. When used for gears, this high endurance strength results in 2 GPa or higher strength (1.5-times conventional products) at the tooth surface, as well as better durability at the base of the tooth. Different combinations of technologies such as metal powder, forming and heat treatment allow high-precision, high-density sintered alloy to be manufactured with a much easier process, making use of the alloy in drivetrain components and other applications.

NTN will coordinate with group company Nippon Kagaku Yakin Co., Ltd.*5 into the future to accelerate the development of products using sintered alloy, as well as the research and development of stronger, higher precision sintered alloy or composite materials. These developments will be used to improve yield, shorten processing times and reduce energy consumption, and applied to the entire product lifecycle in areas such as materials, manufacturing and functionality to help reduce the impact on the environment.

*1:NTN study.

*2:A larger applied stress results in quicker fractures (generation of cracks), while less applied stress increases the time taken for fractures to be generated. If fractures are not generated below a certain stress level, this maximum level of stress amplitude is referred to as the endurance strength, endurance limit or fatigue limit.

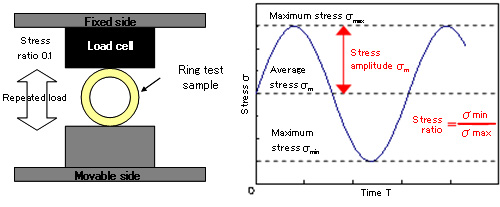

*3:According to results of Ring Compression Test (value with a stress ratio of 0.1). The maximum stress was 700 MPa when subjected to stress amplitude of 315 MPa.

*4:Method that involves pressing and forming powder materials using a mold to form sintered objects fired at a lower temperature than the melting point of the materials. Molds allow products and similar shapes to be manufactured directly with a high degree of precision, and reduce waste of materials or energy consumption during the manufacturing process.

*5:Joined the NTN Group in September 2011. Conducts development of composite materials such as sintered alloys and engineering plastics, and possesses advanced molding and forming technologies.

Features

| (1) Density |

absolute density ratio 95% or higher (world's highest standard) |

|---|---|

| (2) Endurance strength (stress ratio 0.1) |

300 MPa or higher (approximately 2-times conventional products, world's highest standard) |

| (3) Surface pressure strength (slip ratio 25%) |

2 GPa or higher (1.5-times conventional products) |

Applications

Drivetrain and machinery components such as gears, cams and sprockets

Inquiries about this release

Product Photo : Example of small gears made of the world's highest standard “Sintered Alloy”

Test Examples

Fatigue characteristic test method using ring test samples

Image 1. Fatigue tester and stress amplitude

- Movement of the ring test sample was restricted to vertical motion, and load applied repeatedly. The maximum stress that was generated during testing was in pull mode, around the top and bottom sides of the test sample inner diameter.

Fatigue test results (stress ration 0.1)

Image 2. Fatigue test results

Image 3. Sintering conditions