Development of “Laser Scriber for Thin-film Solar Cells*1”March 2, 2012

[High-speed, high-precision laser machining that contributes to a shorter takt time*2]

NTN Corporation (hereafter, NTN) has developed the “Laser Scriber for Thin-film Solar Cells”, which fuses optical and laser machining technologies acquired from the development of high-speed, high-precision table technology and LCD (Liquid Crystal Display) repair devices.

This scriber offers outstanding reliability, high-speed and high-precision scribing that contributes to a shorter takt time during the thin-film solar cell panel manufacturing process, which is expected to improve conversion efficiency and lower costs.

The newly developed “Laser Scriber for Thin-film Solar Cells” features a stage unit for mounting panel substrates that is approximately 50% lighter than large panel substrates usually required for thin-film solar cells. A higher rigidity for the track unit helps to limit vibrations during high-speed operation. These changes give the device much higher performance, with a maximum speed of 3,000 mm/s and rate of acceleration of 2.0 G, and high-precision with straightness at ±10 μm or less.

Three different wavelengths can be selected for the laser mounted to the device, to suit various machining conditions for various types of thin-film materials or scribing processes. In addition to two types of methods available for utilizing multiple laser beams, the “Multiple laser type” and “Laser beam branching type,” the device can be customized a number of ways, including using different lasers specified by the customer, or mounting special optical systems. A touch panel control screen allows operators to set various conditions or check machining status easily.

NTN has maximized the potential of its technical capabilities acquired with its main bearing products and precision machinery, and plans to continue proposing new products for renewable energy such as wind power or solar power generators, a field that is expected to increase in demand into the future.

*1 Laser scriber: device that machines grooves such as electrodes using a laser during the solar cell panel manufacturing process

*2 Takt time: process operating time for achieving the average timing for each production process during manufacturing

Features

- Can be used for large substrates for thin-film solar cells: scribing area 1,400 × 1,100 mm

- The lightweight and high-rigidity properties of table units have been applied for high-speed, high-precision scribing

- Lightweight : approximately 50% reduction (compared to NTN's conventional large stage units)

- High-rigidity : special structure for the track unit

- Speed : 3,000 mm/s (maximum, at the work mounting axis)

- Rate of acceleration : 2.0 G

- Straightness : ±10 μm

- Customizable design to suit thin-film solar cell materials, scribing processes and other requirements

- Uses multiple wavelength lasers : select from three wavelengths, 1064 nm, 532 nm and 355 nm

- Multi-head configuration : available in multiple laser type and laser beam branching type

Individual requests can be met, from sales of units to complete systems, such as large table units, built-in lifter units or alignment mechanisms, and set up using various lasers or optical systems

- Simple operation: set conditions and provide operating instructions using a touch panel

Inquiries about this release

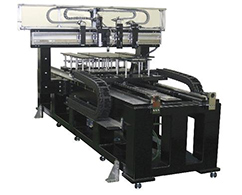

Product Photo

Mechanical unit of the “Laser Scriber for Thin-film Solar Cells”

(dimensions: total length 4,500 × width 1,700 × height 1,750 mm)