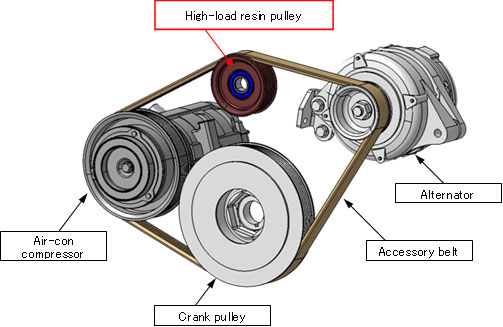

Development of “High-load Resin Pulley” for engine ancillary beltsJanuary 27, 2012

[Highest load resistance in the industry, direct replacement for steel pulleys]

NTN Corporation (hereafter, NTN) has developed the “High-load Resin Pulley” used for engine accessory belt drive systems. These pulleys deliver the highest load resistance in the industry.

With increasing demand for better fuel economy and weight savings in cars, there has been a greater move to replace various steel parts throughout cars with plastic parts. Engine accessory belt pulleys are available in plastic to replace older steel pulleys in line with these moves. Yet the higher power output and rotational speed of engines due to the greater efficiency of engines has often resulted in slip (also known as creep) between the outer ring of the bearing and plastic parts, and additionally deformation of the pulley causes the mating between the outer ring of the bearing and seal to become loose and grease to leak out as the seal rotates.

The “High-load Resin Pulley” developed by NTN uses high-rigidity plastic able to withstand the high temperatures around the engine. It also employs an optimum creep prevention groove on the outer surface of the bearing, and improvements to the outer ring seal groove and seal outer surface shape to prevent pulley deformation. These changes serve to prevent creep and leaking grease under high power output or rotational speeds, while also providing more than sufficient durability and the highest load capacity in the industry, at more than double that of existing plastic pulleys. This allows steel pulleys to be replaced with developed products, resulting in weight savings of approximately 1/3 the original weight.

NTN plans to market and sell the “High-load Resin Pulley” globally as part of efforts to save weight of various car parts, while also contributing to better fuel economy and lower CO2 emissions of cars.

Features

Direct replacement of steel pulleys, and lighter weight

- More than double the high-load resistance of existing plastic pulleys (industry highest)

- Use of high-rigidity plastic

- Optimal creep prevention groove on outer surface of outer ring

- High-rigidity design for the outer ring seal groove and seal

- Lighter weight than steel pulleys (weight comparison: approximately 1/3)

Applications

Pulleys for car engine accessory belts

Inquiries about this release

Product photo

Area of application

Accessory belt drive system