About Sintered Metal

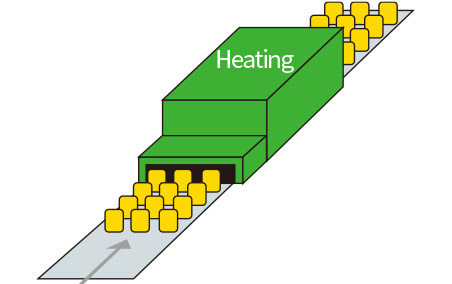

Sintered metal is a general term for products made from compression molded metal powder which is manufactured by heating. By heating metal powder, the powder particles are bonded together to obtain strength and hardness. This process is called sintering. Adjustments of metallic powder types and additives offers a variety of characteristic including low wear and sliding properties.

About BEARPHITE

- NTN's proprietary metal combined with a fine powder of quality natural graphite.

Can be used as bearings, machine parts, and others.

<Origin of BEARPHITE >

Bearing+Graphite⇒BEARPHITE

Mass-production through Processing Method with No Material Wast

BEARPHITE features environment-friendly manufacturing method. Compared to similar products by processing methods such as casting, forging, and turning, BEARPHITE is manufactured by pressing and forming metal powder, so almost 100% of the input materials can be turned into products, making effective use of resources. In addition, the use of highly durable molds realizes mass-production of high precision products in a short period of time.

Feature comparison by processing method

| Casting | Forging | Turning | BEARPHITE | ||

|---|---|---|---|---|---|

| Shape freedom degree | ◎ | 〇 | 〇 | 〇 | |

| Dimensional accuracy | △ | 〇 | ◎ | ◎ | |

| Strength | ◎ | ◎ | ◎ | 〇 |

|

| Cost | 100 units | 〇 | △ | ◎ | △ |

| 10,000 units | △ | 〇 | △ | ◎ | |

| Environmental impact | △ | △ | △ | ◎ | |

Product Lineup

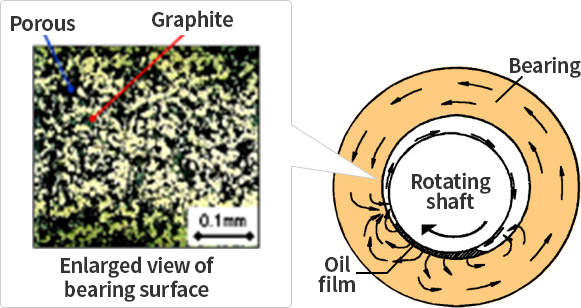

Oil-impregnated sintered bearing (sliding bearing)

- Bearing made from sintered metal, supporting shaft or surface on sliding surface

- Numerous porous inside the bearing allow oil to penetrate the porous

- Oil infiltrated into the porous by rotation of shaft shows up to function as a lubricating oil

- Stable lubricating properties realizes long operating life and wide range of operating temperature

- Self-lubricating, resistant to seizure, maintenance-free operation

- Excellent quietness

- Easy space-saving through customized design

Mini pillow unit

- Lightweight and compact bearing unit combining oil-impregnated sintered bearing and steel housing

- Lineup of three types: mini pillow unit, mini flange unit, and mini side flange unit

- Features lubrication-free, long operating life and easy to install for a wide range of applications

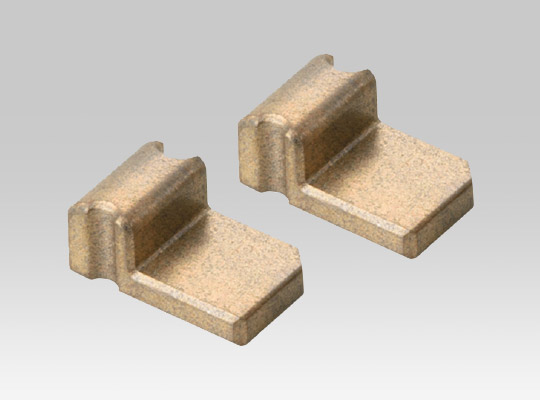

Sintered machine part

- High strength and hardness by our proprietary material (alloy steel powder)

- No turning, grinding, or other machining is required, which is advantageous in terms of cost in mass-production

- Available for various applications by combining materials

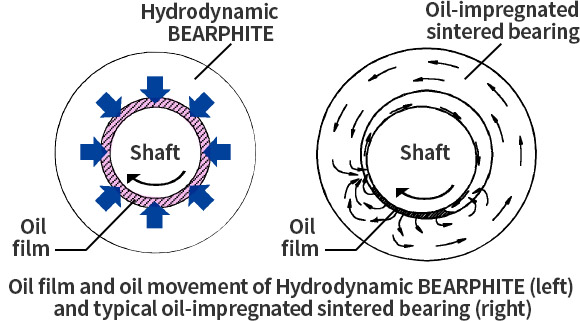

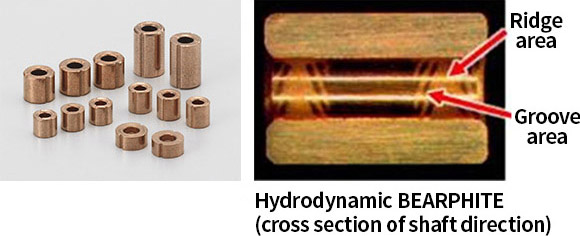

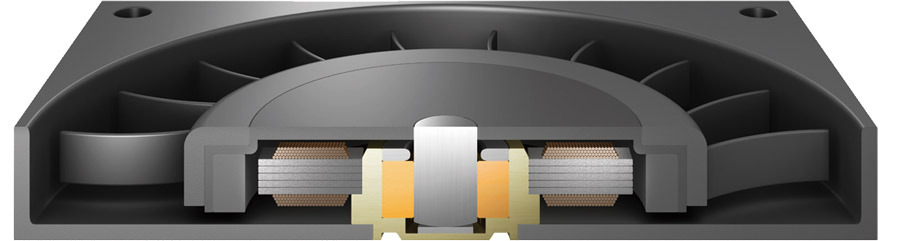

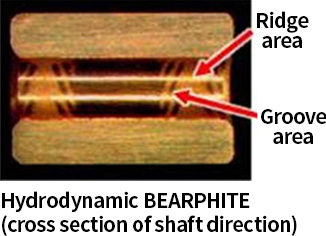

Hydrodynamic BEARPHITE

- Oil-impregnated sintered bearing with herringbone-shaped hydrodynamic grooves of a depth of several micrometers on inner surface

- High rotational accuracy, low noise, and long life, even at high rotational speeds by forming oil film around the entire bearing clearance due to dynamic pressure generated by the grooves, which supports shafts contactlessly during operation

Global Production System

We also produce high precision products at NTN Advance Materials Corp. in Japan and NTN MANUFACTURING (THAILAND)CO., LTD. to respond to demand globally.

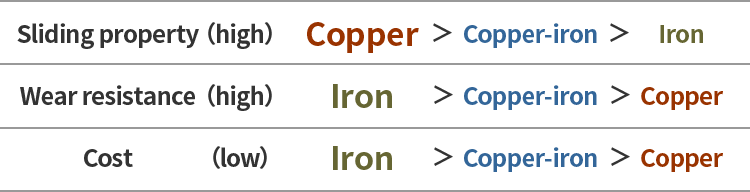

Typical Material Features and Applications

Materials

| Type | Features | Applications |

|---|---|---|

Copper

|

Copper and tin based material with additives of graphite, molybdenum disulfide, nickel, phosphorus, etc. according to applications Feature low friction, quietness, and wear resistance |

|

Copper-iron

|

Copper and iron based material Amounts of iron is increased according to applications Feature excellent wear resistance and low cost |

|

Iron

|

Iron based material with additives of copper and graphite according to applications Feature excellent wear resistance and impact resistance |

|

Oil-impregnated sintered bearing (sliding bearing)

| Material name | Base material | Features | Applications |

|---|---|---|---|

| BEARPHITE H | Copper |

|

|

| BEARPHITE HZ16 | Copper |

|

|

| BEARPHITE CL01 | Copper-iron |

|

|

| BEARPHITE EC | Copper-iron |

|

|

| BEARPHITE EZ06 | Copper-iron |

|

|

| BEARPHITE LB | Iron |

|

|

Sintered machine part

| Material name | Base material | Features | Applications |

|---|---|---|---|

| BEARPHITE FG68 | Iron |

|

|

| BEARPHITE Z24 | Iron |

|

|

| BEARPHITE Z34 | Iron |

|

|

| BEARPHITE S01 | Iron |

|

|

Hydrodynamic BEARPHITE

| Material name | Base material | Features | Applications |

|---|---|---|---|

| EZ06 | Copper-iron |

|

|

| EZ17 | Copper-iron |

|

|

| B05 | Copper-iron |

|

|

Application Examples

Automobile

Headlight (AFS*)

*AFS: Adaptive Front Lighting System

Self-lubrication BEARPHITE for sliding part

It can be used in the environment where the use of oil is difficult by adopting special graphite for the first time in the sintered metal industry to optimize material composition.

Cooling fan motor

Hydrodynamic BEARPHITE

It realizes high reliability over a wide range of temperatures for a long period of time by adopting lubricating oil with less viscosity loss and evaporation at high temperatures.

Wiper motor/Power window motor

Oil-impregnated sintered bearing for various electric motor

It is made from proprietary material featuring an added high quality fine graphite powder to provide reliable lubrication for longer bearing life and excellent bearing performance across all temperature ranges.

Fuel pump

Corrosion resistance BEARPHITE for rotor

It features excellent corrosion resistance in gasoline fuel by applying aluminum bronze, which has excellent corrosion resistance to sintered bearing. It realizes stable sliding friction characteristic by optimizing the material composition.

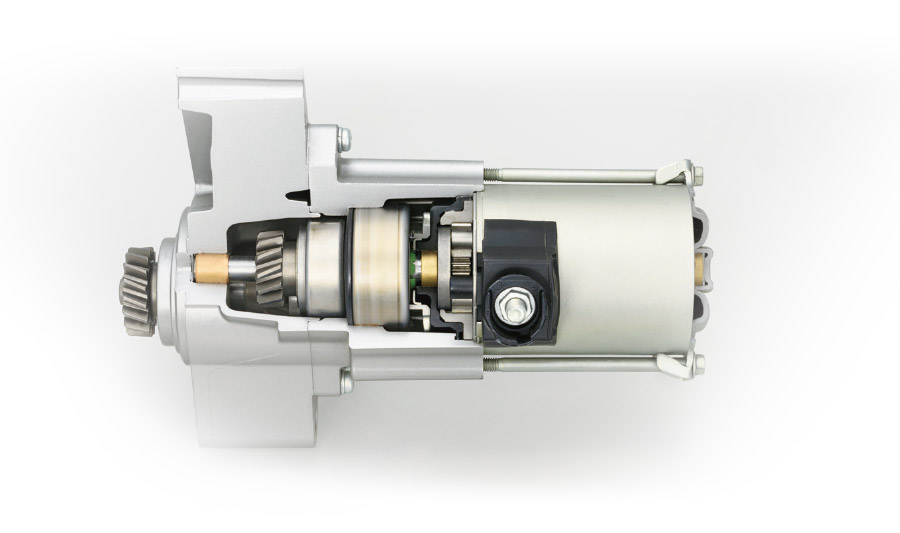

Starter motor

High density, high strength sintered gear for planetary reduction gear

It features higher density with unique material and special manufacturing concepts for high strength and longer operating life. It contributes to cost reductions by replacing forged and grinded parts.

BEARPHITE CL (Copper Layer) for rotor

Small quantity of unique copper powder creates a copper film on the surface for outstanding sliding characteristics and excellent wear resistance.

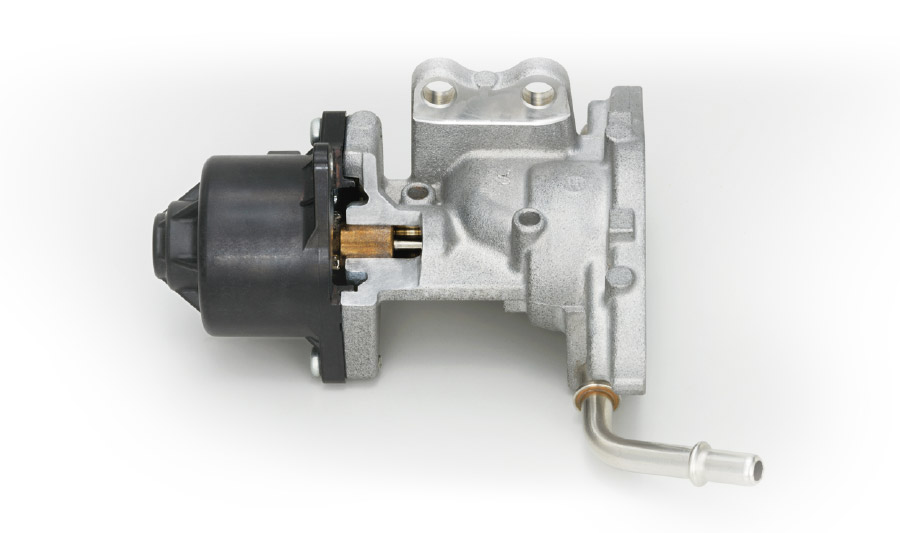

Exhaust gas recirculation valve

Self-lubrication BEARPHITE for sliding shaft

It can be used in the environment where the use of oil is difficult by adopting special graphite for the first time in the sintered metal industry to optimize material composition.

General-purpose engine

Connecting rod unit

It features high density and high strength by using proprietary material and manufacturing process. By supplying as unit with bearing, it contributes to reduceing the number of person-hours required for assembly by users.

Construction machinery

Mini-pillow for control lever support

It can be easily mounted by integrating an oil-impregnated sintered bearing into the high rigidity steel plate housing. It features lightweight, compact and self-aligning for long operating life without additional lubrication.

Information device

HDD

Hydrodynamic BEARPHITE for HDD spindle motor

Hydrodynamic grooves are located on the internal diameter and one end face help to support the rotary shaft in a non-contact condition in the both radial and thrust directions by using the effect of hydrodynamic pressure, for high rotational precision, low noise and long operating life.

Cooling fan motor

Hydrodynamic BEARPHITE for fan motor

Hydrodynamic grooves are located on the internal diameter to support the rotating shaft in a completely non-contact condition in the radial direction by using the effect of hydrodynamic pressure, for low noise and long operating life.

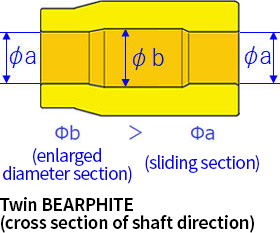

Twin BEARPHITE

It has enlarged diameter section between the sliding sections on the inner diameter surface. As the inner diameter is larger than the sliding section, it reduces sliding area and contribute to low power consumption.