Radial roller bearings

Cylindrical roller bearings

These use rollers as the rolling elements and have a high load capacity. The rollers are guided by the ribs of the inner or outer ring. The inner and outer rings can be separated to facilitate assembly, and both can be fitted tightly.

On types with no ribs, either the inner or the outer ring can move freely in the axial direction, making cylindrical roller bearings ideal for use in free side bearings that absorb shaft expansion.

On types with ribs, the bearing can bear a slight axial load between the roller end surfaces and the ribs. Cylindrical roller bearings include the HT type that modifies the shape of roller end surfaces and ribs to increase axial load capacity, and the E type that has a special internal design to increase radial load capacity. The E type is standard for small-diameter sizes.

- Related Catalog

Double row cylindrical roller bearings

These are used in the printing cylinders of printing machinery, rolling mill rolls, and the main shafts of machine tools, where thin-walled bearings are required. In the main shafts of machine tools, the radial inner clearance is adjusted by pushing the tapered shaft into the inner ring of the tapered bore.

- Related Catalog

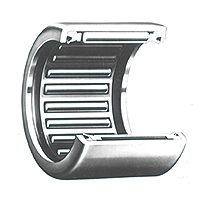

Needle roller bearings

These bearings use small needle rollers, 6mm or less in diameter with a width 3 to 10 times diameter, as rolling elements. As such, they feature low cross-section height, high load capacity relative to dimensions, and high rigidity due to the number of elements, and are suited to wobbling or pivoting motion.

- Related Catalog

Tapered roller bearings

Tapered roller bearings are designed so the inner and outer ring raceway and the apex of the tapered rollers intersect at one point on the bearing centerline. For this reason, the rollers are pushed against the inner ring rib and roll guided by the rib, receiving the loads from the inner ring raceway surface and the outer ring raceway surface as a combined load on the raceway surface.

Component force is produced in the axial direction when a radial load is applied, so the bearings must be used in pairs. The inner ring with rollers and outer ring separate, facilitating mounting with clearance or preload. However, assembled clearance is hard to manage and calls for attention. Tapered roller bearings are capable of supporting large loads, both axial and radial.

- Related Catalog

Double row tapered roller bearings

These have outward-facing types (for double-row outer ring use) and inward-facing types (for double-row inner ring use). As the inner clearance is adjusted to a set value, the bearings must be used in combination with components of the same product number, as marked.

In addition to duplex bearings that combine a pair of single row tapered roller bearings, there are also four-row tapered roller bearings composed of two double-row inner rings, one double-row outer ring, and two single-row outer rings. Four-row tapered outer bearings are used in high-load applications such as rolling mill roll necks.

- Related Catalog

Spherical roller bearings

These bearings have an outer ring with a spherical track surface, and an inner ring that encloses two rows of barrel-shaped rolling elements.

Various types exist that differ by internal design, including bearings with a tapered bore inner caliber. The bearings are easily mounted on the shaft with an adapter or un-mounting sleeve, and are used in many industrial machines for their high load capacity. Potential troubles include one row bearing no load when axial load is large, calling for attention to usage conditions.

- Related Catalog