Damage to Reteiners

Damage to Reteiners

|

Condition

|

Cause

|

Solution

|

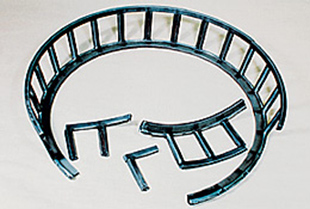

- Retainer of angular contact ball bearing

- Breakage of machined high tension brass casting retainer L1

- The cause is poor lubrication.

- Retainer of spherical roller bearing

- Breakage of partitions between pockets of pressed steel retainer

- Retainer of tapered roller bearing

- Breakage of pockets of pressed steel retainer

- Retainer of cylindrical roller bearing

- Breakage of partitions between pockets of machined high tension brass casting retainer L1.