Electrical Pitting

Electrical Pitting

|

Condition

|

Cause

|

Solution

|

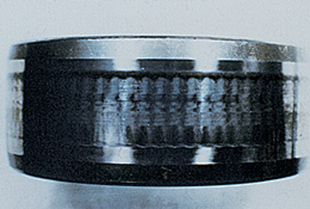

- Inner ring of cylindrical roller bearing

- Raceway surface is corrugated by electric pitting

- Rollers of tapered roller bearings

- Electric pitting at middle of rolling contact surfaces

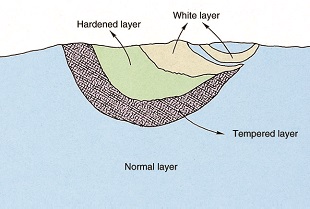

- Magnified (x400) pitting of roller shown in Photo 5

- Nital etchant develops a white layer on the cross section

- Explanation of magnified photo 6