NTN Receives Grand Award of 2022 ‘CHO’ MONODZUKURI Innovative Parts and Components AwardsOctober 28, 2022

NTN Corporation (hereafter, NTN) received the “Grand Award” at the “2022 ‘CHO’ MONODZUKURI Innovative Parts and Components Awards” hosted by the MONODZUKURI Nippon Conference and Nikkan Kogyo Shimbun, Ltd.

Awarded Product

High Efficiency Fixed Type CVJ “CFJ”

Product Overview

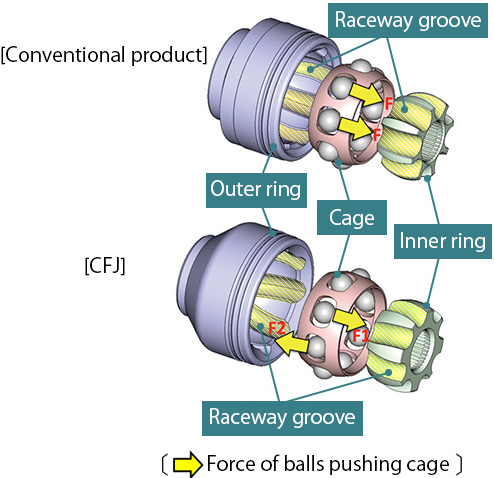

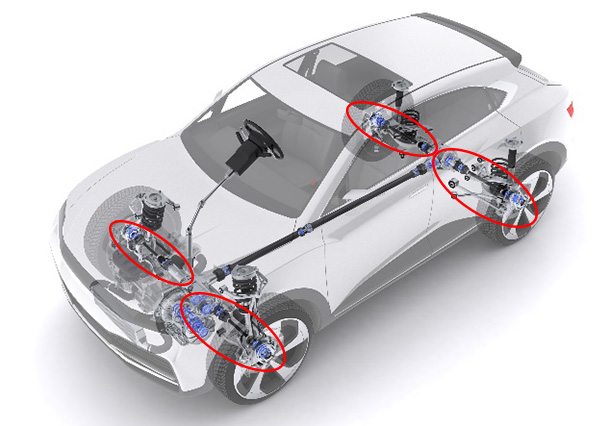

“CFJ” is a fixed type constant velocity joint (CVJ) that contributes to fuel and electricity saving in automobiles with the world's highest level of efficiency. CVJ is a component of driveshaft that transmits power (torque) of powertrain unit such as engine and motor to tires. Fixed type CVJ is used on the tire side and transmits torque while maintaining constant rotation at high-operating angle. The conventional CVJ generates torque loss, as force applied to internal parts during torque transmission is generated in one direction. Additionally, the loss tends to increase as the operating angle increases.

“CFJ” has greatly changed the basic structure of conventional CVJ by adopting proprietary “Spherical Cross Groove Structure*” that cancels the force applied to internal parts. By applying this structure, it is possible to reduce torque loss rate by more than 50% while maintaining the world's best level of lightweight and compactness of the conventional product. Furthermore, CFJ greatly suppress the increase in torque loss rate even at high-operating angle.

* Structure where the spherical ball raceway grooves through which balls pass intersect each other on inner ring and outer ring. Adjacent raceway grooves are inclined with each other to distribute directions of forces from balls alternately and cancel them.

High Efficiency Fixed Type CVJ “CFJ”

High Efficiency Fixed Type CVJ “CFJ”

Reasons for Receiving the Award

Toward realizing carbon-free society, the automotive industry has been accelerating its efforts to reduce CO2 emissions and improve fuel and electricity consumption. Accompanied with this trend, automotive components are required to achieve high-efficiency. “CFJ” reduces torque loss rate by more than 50% compared to the conventional product while maintaining lightweight and compactness of the conventional product, and greatly contributes to improving automobile fuel efficiency and reducing CO2 emissions. In addition to this environmental contribution, the originality of the “Spherical Cross Groove Structure” technology, which has achieved the world's highest level of efficiency, is highly evaluated.

Features

| High-efficiency | 50% reduction in torque loss ratio compared to the conventional product (world's highest level) |

|---|---|

| Lightweight and compactness | Equivalent to the conventional product (world's best level) |

| Operating angle | Equivalent to the conventional product (up to 47°) |

Applied area

Structural comparison

with conventional product