NTN Develops Large Diameter Deep Groove Ball Bearings for Coaxial e-AxlesMay 27, 2024

- Realizing a high speed rotation supporting dmn value*1 of 1.5 million and providing more than 50% lower torque than standard products

- Contributing to reduction in size and weight of coaxial e-Axles, while improving efficiency and extending the cruising distance of EVs

NTN Corporation (hereafter, NTN) has developed a large diameter deep groove ball bearing for the coaxial e-Axle, a key driving source in electric vehicles (EVs). These bearings are designed to support high speed rotation with a dmn value of 1.5 million and provide more than 50% lower torque compared to standard products. Additionally, the large diameter bearing is resistant to electrical pitting. This product contributes to the reduction in size and weight of coaxial e-Axles. As a result, it enhances the efficiency of the e-Axle and extends the cruising distance of EVs by facilitating high speed rotation while maintaining low torque.

- dmn value: An indicator that expresses the rotational performance of bearings and is multiplied bearing pitch circle diameter (mm) by rotational speed (min-1)

Large diameter deep groove ball bearings for coaxial e-Axles

Large diameter deep groove ball bearings for coaxial e-Axles

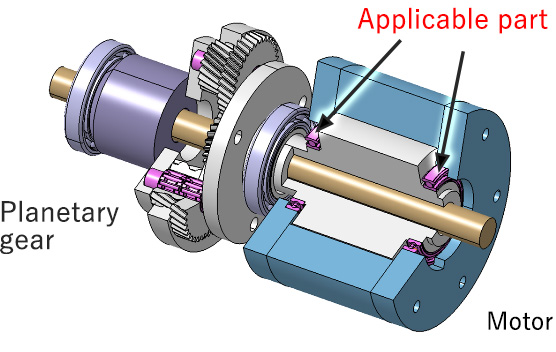

Applicable parts in the parallel coaxial e-Axle

Applicable parts in the parallel coaxial e-Axle

Background of development

In recent years, coaxial e-Axles have emerged as a compact and lightweight driving source, with the aim of extending the cruising distance of EVs. The coaxial e-Axle consists of a motor and a planetary reduction gear with the output shaft of reduction gear passing through the motor shaft. Thus, the bearings used in the coaxial e-Axles are larger in diameter with an inner diameter of 50 mm to 90 mm, as compared to those used in the parallel-axis e-Axles.

As efforts to further extend the cruising distance of EVs intensify, there is an increasing expectation for e-Axles to become more compact and lightweight, to improve efficiency. Therefore, large diameter bearings for coaxial e-Axles need to adapt to the higher power output of motors, lower torque, and electrical pitting *2.

- A phenomenon where sparks generated by the current leakage from the motor cause the raceway surface to melt, leading to damage such as spalling.

Features

| 1. High speed rotational performance | This product reduces the centrifugal force applied to the retainer during high speed rotation by decreasing the number of rolling elements (balls) used, and the number of retainer pockets. Additionally, the design and material of the retainer have been optimized to minimize deformation due to centrifugal force at high rotational speed, ensuring the required strength. As a result, this large diameter bearing, with an inner diameter of 50 mm to 90 mm, achieves a dmn value of 1.5 million, more than double that of standard products. |

|---|---|

| 2. Low torque | This product realized a 50% decrease in torque compared to standard products by reducing the number of balls used. |

| 3. Electrical pitting resistance |

This product prevents electrical pitting by utilizing ceramic rolling elements which are insulators. |

As the adoption of coaxial e-Axles is expected to accelerate in the future, NTN is set to introduce this product on a global scale. Recognizing the growing demand for further downsizing, weight reduction, and enhanced efficiency in coaxial e-Axles, NTN plans to contribute to extending the cruising distance of EVs and promoting their widespread use.

Application

Coaxial e-Axles for EVs (motors)

Structure

Comparison with standard bearing