NTN Begins Sales of Aluminum Composite-type Plastic Sliding ScrewFebruary 14, 2024

- Excellent load capacity, durability, and heat dissipation realized by integrally molding aluminum alloy and original plastic material

- Preparing various size lineup to adapt to usage situations with high speed and high load!

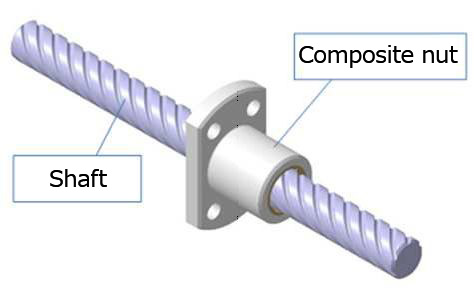

NTN Corporation (hereafter, NTN) has developed and began sales of the aluminum composite-type plastic sliding screw, which integrates aluminum and NTN's original compounded PPS*1 plastic material. In addition to features of plastic sliding screws such as quietness and greaseless, this product has excellent load capacity and durability and heat dissipation. NTN will propose this product for a wide range of applications, including medical equipment and semiconductor-manufacturing equipment, as a series product for usage situations with high speed and high load.

- Abbreviation for Poly Phenylene Sulfide. It is thermoplastic resin manufactured by injection molding with continuous-use temperature of 230°C. It has excellent heat resistance, chemical resistance, and electrical insulation properties.

Aluminum composite-type plastic sliding screw

Aluminum composite-type plastic sliding screw

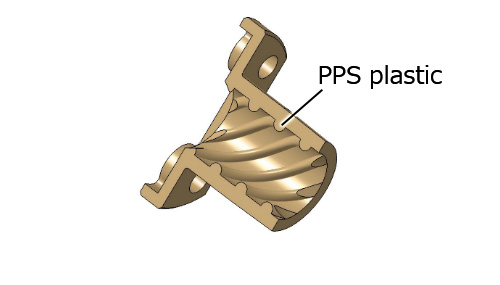

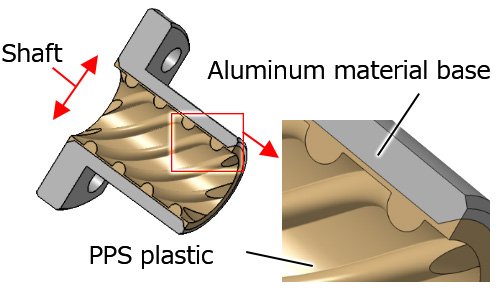

Construction of aluminum composite-type

Construction of aluminum composite-typeplastic sliding screw

Background of development

Plastic sliding screws convert rotary motion from applications such as motors into linear motion. It has quietness and greaseless, therefore our products have been adopted in many types of transportation equipment in medical, semiconductor-manufacturing, and food machinery fields.

NTN has developed the aluminum composite-type plastic sliding screw that offers better load capacity, durability, and heat dissipation than sliding screws whose nut are made only of plastic (plastic-only type). After providing prototypes and adding improvements, we have begun sales of the aluminum composite-type plastic sliding screw.

This product uses a composite nut made by integrally molding aluminum alloy base material and PPS plastic material. By adopting special surface treatment, it achieves excellent adhesion of the two materials. As we have made this series of products with a variety of size lineup same as the plastic-only type, it can be used in a wide range of usage situations including not only replacement, but also high speed moving and high load areas.

Features

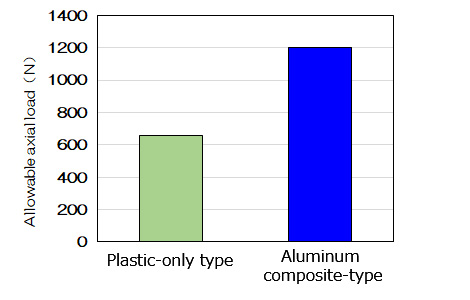

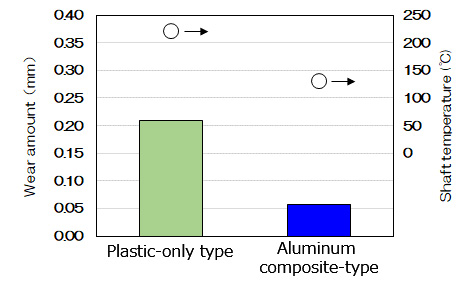

| 1. Load capacity and durability | Through integrally molding aluminum alloy as base material and NTN's original compounded PPS plastic material, allowable axial load is improved by 80%*2 compared to the plastic-only type. By using base material made of aluminum alloy, it reduces temperature rise in sliding parts, and wear amount is reduced by 70%*2 compared to the plastic-only type, realizing long operating life. |

|---|---|

| 2. Heat dissipation | By using aluminum alloy base material, heat dissipation is improved by 40%*2 compared to a plastic-only type. It can reduce the impact of sliding heat on peripheral components and machinery. |

| 3. Greaseless and quietness | It can be used without grease like plastic-only type, and contributing to reduction in maintenance frequency. Additionally, as PPS plastic material has low coefficient of friction, it has high quietness as with the plastic-only type. |

- In case of the product specification with 12 mm axis and 2 mm lead. Lead means distance that the nut moves in linear direction when it makes one rotation. The figures depend on product specifications and usage situations.

NTN will propose this product for various transportation equipment used in medical, semiconductor-manufacturing, and food machinery fields to contribute to higher functionality such as high speed movement. Additionally, we will respond to growing demand in robot and transportation equipment market due to automation and labor saving, while contributing to the progress of the market by expanding product lineup.

Application

Transportation equipment for medical, semiconductor-manufacturing, and food machinery fields

Comparison with plastic-only type

Plastic-only type sliding screw

Plastic-only type sliding screw(Use plastic material only for nut)

Aluminum composite-type plastic sliding screw

Aluminum composite-type plastic sliding screw (Use composite nut made by integrally molding

aluminum alloy and plastic material)

Comparison of performance with plastic-only type (typical example: 12 mm shaft diameter and 2 mm lead)

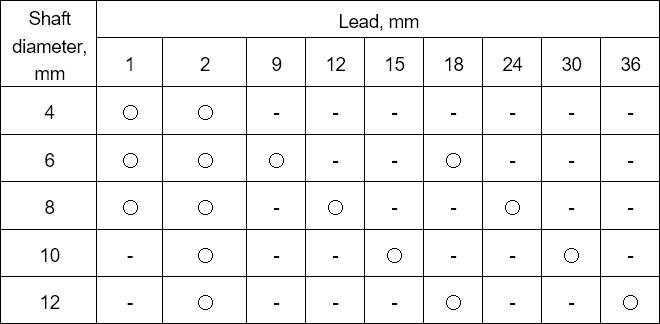

Specifications of the aluminum composite-type plastic sliding screw