NTN Develops “Needle Roller Bearing Unit for e-Axle Planetary Reduction Gear” for EVs·HEVsJune 21, 2023

- Improved peeling resistance, high speed rotational performance, and moment load resistance

- Adapt to usage environment of coaxial e-Axle which is increasingly harsh due to miniaturization and high speed

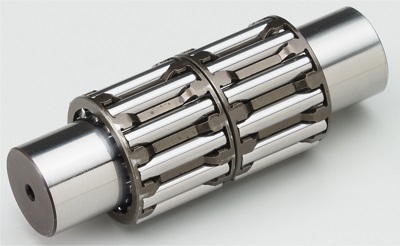

NTN Corporation (hereafter, NTN) has developed “Needle Roller Bearing Unit for e-Axle Planetary Reduction Gear” which is used in electric vehicles (EVs) or hybrid electric vehicles (HEVs). This product, a set of needle bearing (needle roller with cage) and shaft, has been developed by making improvements on cage, roller and shaft to enhance peeling resistance, high speed rotational performance, and moment load resistance. It adapts to usage environment of coaxial e-Axle, which is increasingly severe for more compactness and high speed, and contributes to the reduction of fuel efficiency or energy costs.

“Needle Roller Bearing Unit for

“Needle Roller Bearing Unit fore-Axle Planetary Reduction Gear”

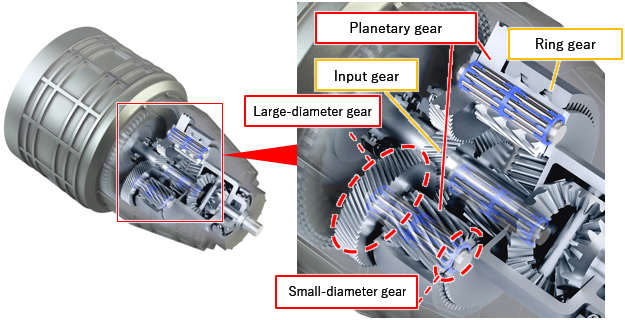

Coaxial e-Axle (marked in red)

Coaxial e-Axle (marked in red)

Background of Development

In EVs or HEVs, which have become popular in recent years, e-Axle that integrates motor, inverter, and reduction gear as the main drive source are increasingly used. Among e-Axles, needle roller bearings with small cross-sectional heights and high load capacities are used for coaxial e-Axle that use planetary reduction gear.

In coaxial e-Axle, lubricating oil is becoming less viscous to improve efficiency, so that the oil film becomes thinner. It causes that the raceway surface of the bearing and rolling elements come into direct contact with each other, resulting in minute spalling (peeling) and cracking that can damage the bearing. In addition, the downsizing and higher power output of e-Axle in line with the reduction in fuel efficiency and electricity costs of vehicles require the bearing to be high speed rotation compliant. In addition, helical gears with a helical tooth trace are used for planetary gears to ensure quietness, but when gears with a helical tooth trace to the shaft engage with each other, moment load to tilt the gear is applied to the bearing. In addition, as coaxial e-Axle uses a stepped planetary gear which is axially long in order to obtain a large reduction ratio, it uses long shaft which tends to be bent when it receives load. The moment load and shaft deflection raise the surface pressure near roller chamfer of the bearing, and the resulting reduction in bearing operating life is also an issue.

Features (compared to conventional products)

| 1. Peeling resistance | The peeling life has been improved by approximately 30% as its durability to surface-damage caused by contamination has been enhanced by optimizing heat treatment of the shaft. |

|---|---|

| 2. High speed rotational performance | High speed rotational performance has been improved by approximately 10% by enhancing the fatigue strength of cage with change of the material, optimized design of welds and heat treatment. |

| 3. Moment load resistance |

The bending* of shafts by plastic deformation has been reduced by approximately 70% by changing material of shafts in addition to optimizing crowning shape of roller. It reduces surface pressure and prevents life reduction when moment load applied to the bearing. * A phenomenon in which the shaft is bent and plastically deformed by long-term use under high temperature and high load |

NTN will propose this product globally as an optimal product for planetary reduction gear of coaxial e-Axle, and will contribute to miniaturization and speeding up of e-Axle, leading to saving fuel and electricity costs in EVs·HEVs.

Application

Planetary reduction gear for e-Axle

Reference

Coaxial and parallel-axis e-Axle

There are two types of e-Axle: “Coaxial e-Axle” in which a planetary reduction gear and the motor's output shaft are placed coaxially, and “Parallel-axis e-Axle” in which the speed is reduced using several axes. Compared to the “Parallel-axis e-Axle,” the “Coaxial e-Axle” has the advantage of making e-Axle more compact.

Planetary reduction gear of e-Axle

The planetary reduction gear of the coaxial e-Axle consists of three parts: the gear that inputs the rotation from the motor, the planetary gear that decelerates the input rotation, and the ring gear that is fixed to the housing. The planetary gear has two gears (a large-diameter on the input gear side and a small-diameter gear on the ring gear side) and reduces speed twice to create a large reduction ratio, producing the required torque. As the planetary gear uses two gears, it needs long shaft.