NTN Develops “Twin Arm Auto Tensioner for Accessory Drive Belt System”June 2, 2023

- Adjust belt tension optimally in each driving mode of MHEVs, contributing to improvement of fuel efficiency

- Adopt industry's first mechanism to suppress excessive belt runout which causes abnormal noise and vibration

NTN Corporation (hereafter, NTN) has developed “Twin Arm Auto Tensioner for Accessory Drive Belt System” that automatically and optimally adjusts belt tension of the accessory drive belt system used in engines of mild hybrid electric vehicles (MHEVs). In addition to interlocking mechanism of the two arms, the product adopts industry's first mechanism that suppresses excessive belt runout to adjust belt tension of the accessory drive belt optimally in each driving mode of MHEVs, and contributes to reduction of vibration and noise of engine and improvement of fuel efficiency.

“Twin Arm Auto Tensioner

“Twin Arm Auto Tensionerfor Accessory Drive Belt System”

Accessory drive belt system used in MHEVs

Accessory drive belt system used in MHEVs(Composed of accessory drive belt and pulleys)

Background of Development

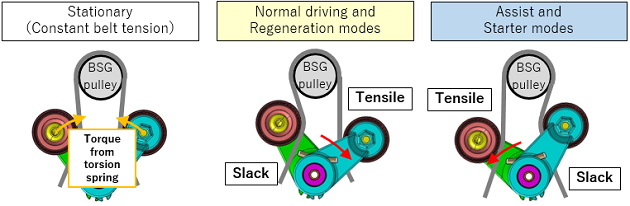

The accessory drive belt system in engines uses auto tensioners to provide belt with the proper tension by adjusting the position of tensioner pulleys. As the force provided from auto tensioners to belts has effects on fuel efficiency, auto tensioners are required to provide proper tension for belts with less force.

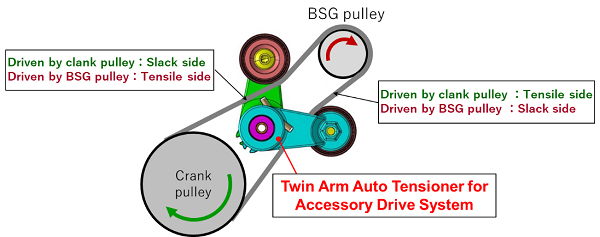

In MHEVs where motors assist engines, either crank pulleys or belt starter generator (BSG*) pulleys are used as driving pulleys, and that is decided according to driving modes of MHEVs. When the driving pulley is switched, the slack positions of the belt are also switched accordingly. In order to adjust belt tension at two positions, two of the conventional auto tensioners are required, which increases engine weight and person-hours for assembling the auto tensioners to engine.

* Collective term of accessory equipment with functions of generator and starter-motor which restarts engine from idling stop by rotating crank shaft

In MHEVs, the driving pulley is switched to the crank pulley or BSG pulley according to driving modes

The slack and tensile positions of the belt are also switched

Features

| 1. Improve fuel efficiency |

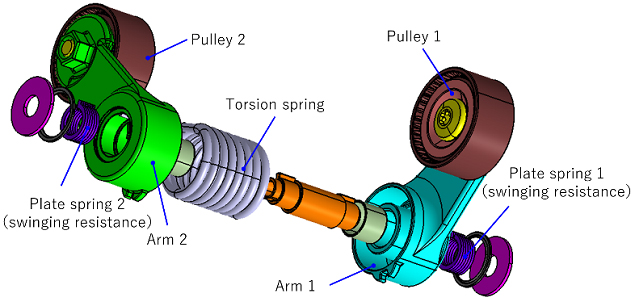

Two sets of arms and tensioner pulleys are combined, and the movement of one arm is interlocked with the movement of another arm. With the mechanism, when the belt on one side is tensile, the arm that a pulley touches the belt in this side swings, and swinging another arm making it possible to adjust slack of the belt in other belt. This mechanism enables auto tensioner to provide belts with proper tension to improve fuel efficiency.

|

|---|---|

| 2. Quietness | With adopting industry's first proprietary mechanism to suppress excessive swing of arms, suppressing excessive runout of the belt which causes abnormal noise and vibration. |

| 3. Lightweight | The weight is reduced by approximately 60% compared to the use of two conventional auto tensioners, which also contributes to improvement in fuel efficiency |

Examples of accessory drive belt system applying the developed product

When the belt is pulled by driving pulley in each driving mode, the pulled side belt pushes tensioner pulleys and then arm arms swung, and another tensioner pulley automatically adjusts the slack of belt

In recent years, the use of electric powered vehicles has been rapidly spreading in automotive market with the aim of reducing CO2 emission. Since MHEVs have few change points from the conventional vehicles, the number of MHEVs production is forecasted to increase further in the future.

NTN will propose the developed product globally as a product that supports the spread of MHEVs and contribute to the further improvement of fuel efficiency and the comfort of automobiles.

Application

Tension adjustment for accessory drive belt of engines for mild hybrid vehicles (MHEVs)

Reference

Driving modes of MHEVs

In MHEVs, there are the starter mode where the engine is restarted by the motor, the assist mode where the torque of the engine is supported when accelerating, and regeneration mode when deceleration, in addition to the normal driving mode where the vehicle is driven by force of the engine. In normal driving mode and regeneration mode, the engine is used as the driving source. In starter mode and assist mode, the belt starter generator (BSG) is used as the driving source. The driving source is switched according to the driving modes of MHEVs, therefore, the belt is slack at different positions.

Roles of auto tensioners in accessory drive belt system

The accessory drive belt system transmits the driving force of crankshaft of engine through pulleys and belt to drive accessory equipment such as air compressor and water pump. Insufficient belt tension in the accessory drive belt system causes between belt and pulley slipping and large belt vibration, which lead to deterioration of quietness. On the other hand, the higher the tension, the greater the friction loss when driving the belt. This results in deterioration of fuel efficiency. For this reason, the accessory drive belt system uses auto tensioners, which automatically adjusts the tensioner pulley position to provide the belt with proper tension.