NTN Develops “IMT Bearing,” Ball Screw Support Rolling Bearing for Injection Molding MachineJune 13, 2023

Achieve long operating life by adopting separator retainers for the first time in the industry and reviewing internal design

NTN Corporation (hereafter, NTN) develops “IMT*1 Bearing,” Ball Screw Support Rolling Bearing for Injection Molding Machine which achieves industry's best level in long operating life and high speed rotational performance by adopting separator retainers*2 for the first time in the industry. It contributes to the reduction of maintenance costs and shortening cycle time of electric injection molding machines as well as adapting to usage environment requiring cleanliness.

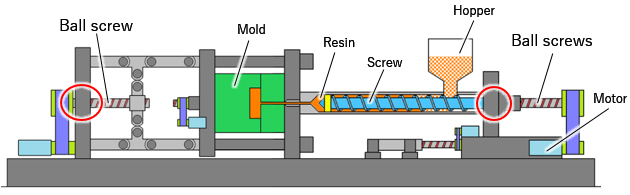

Injection molding machines are used to manufacture plastic products. Toward saving energy and reducing environmental impact, electric injection molding machines are mostly used instead of the conventional hydraulic type. The electric injection molding machines use ball screws and servomotors. In order to improve productivity, they are required to reduce its maintenance cost and shorten cycle time, thus bearings for ball screws of the machines need to achieve long operating life and high speed rotational performance. Additionally, injection molding machines are increasingly used in industrial clean rooms mainly in the medical and food fields, so there is a growing need to prevent lubricating grease of bearings from leaking out.

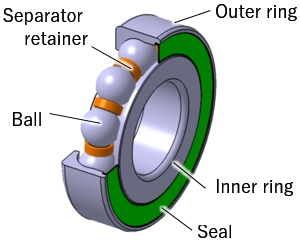

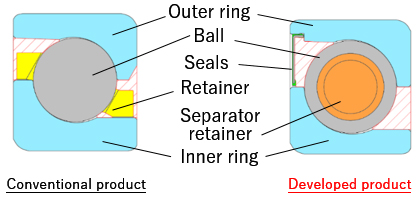

“IMT Bearing,” Ball Screw Support Rolling Bearing for Injection Molding Machine improves both operating life and permitted rotational speed, and prevents grease from leaking out by reviewing the internal design, and adopting separator retainers and seals. Through reviewing internal design including size and number of balls, the axial basic dynamic load rating has been increased by approximately 1.2 times compared to the conventional product, rating life by approximately 1.7 times, and permitted rotational speed by approximately 1.8 times, achieving both high load capacity and high speed rotational performance.

Furthermore, the use of separator retainers increases the inner space volume by approximately 30% compared to the conventional product with integrated retainer. Separator retainers can reduce the width dimension compared to commonly used ring-shaped retainer (integrated retainer). This is the first time to adopt separator retainers to ball screw support rolling bearings for injection molding machine in the industry. By adopting separator retainers, the product can be equipped with a seal to prevent grease from leaking out without changing bearing dimensions, thus keeping environment around the bearing clean. In addition, the amount of filled grease can be increased, so the grease life is also improved.

Most of injection molding machines are already electrified in Japan. In the future, they will be electrified in areas such as China and Europe as well, so demand for ball screw support bearings is expected to expand further. NTN will propose the developed product globally, and contribute to improving the productivity and reducing running costs of electric injection molding machines.

- Abbreviation of Injection Molding Thrust ball bearing

- Retainer that is split and installed between ball, unlike ring-shaped integrated retainer

Features (* Compared to the conventional product)

| 1. Long operating life |

|

|---|---|

| 2. Adapt to clean environment (preventing grease from leaking out) | Equipped with a seal on one side of the bearing by adopting separator retainers |

| 3. High speed rotational performance | Improve permitted rotational speed by 1.8 times* by reviewing internal design |

| 4. Compatibility | Can be replaced with conventional bearing which is not equipped with a seal |

Application

Ball screw for injection molding machine support

Product photo

Structure (cross-sectional view)

Applied area (in red circle)