NTN Develops “Multi Track Magnetic Encoder Integrated Rolling Bearing”November 4, 2022

Contribute to improvement of performance and downsizing/lightweighting of robots with excellent environmental resistance and high-resolution angle detection

NTN Corporation (hereafter, NTN) has developed “Multi Track Magnetic Encoder Integrated Rolling Bearing” with excellent environmental resistance and high-resolution angle detection. The bearing unit integrates bearing with magnetic type encoder, and contributes to improvement of performance, downsizing/lightweighting of robots, and saving man-hours in assembly and setup.

In recent years, the use of robots has accelerated to realize automation and labor saving at manufacturing sites in various industries, reflecting the declining ratio of working-age population in line with decreasing birthrate and aging population, and the types of works which robots take on are becoming diverse. Each robot is required not only to improve motion accuracy, but also to reduce the number of components in joints, size/weight of each component, and man-hours in its assembly process.

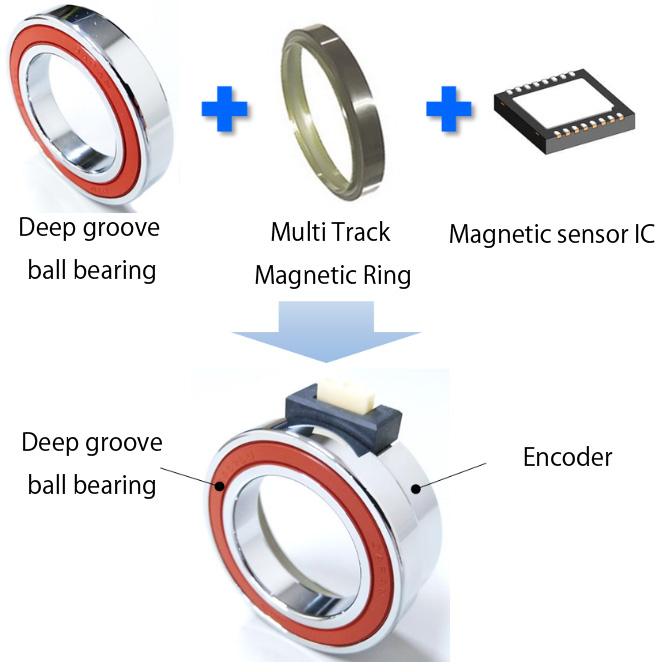

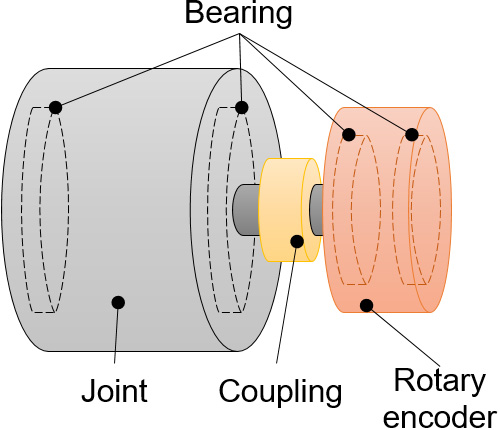

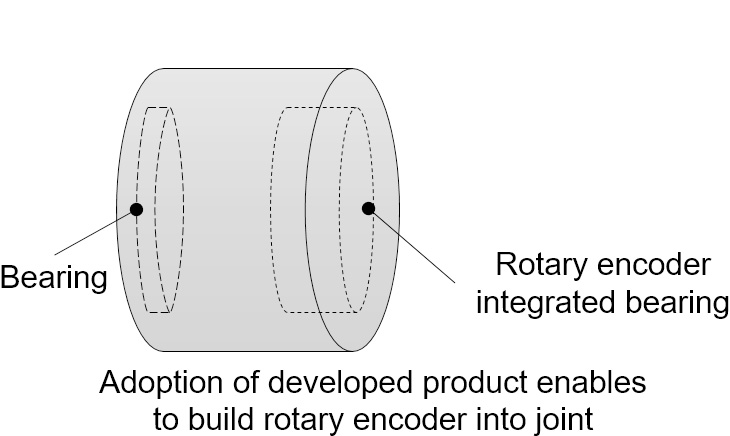

The newly developed “Multi Track Magnetic Encoder Integrated Rolling Bearing” is a bearing unit which integrates a deep groove ball bearing that supports robot joints with magnetic ring and sensor. It can detect rotational speed, direction, and absolute angle. By attaching NTN's proprietary “Multi Track Magnetic Ring *1” to inner ring of bearing and reading changes in magnetic poles of “Multi Track Magnetic Ring” with magnetic sensor IC equipped with outer ring, the product can detect rotational speed and absolute angle with industry's highest level in angle detection resolution (maximum 20bit, resolution of approximately 0.00034°). By utilizing technology for integration of bearings cultivated with Integrated Rotation Sensor Bearings*2, which are adopted in transport equipment such as forklifts, NTN optimizes the gap and directions of “Multi Track Magnetic Ring” and magnetic sensor IC to realize compact and lightweight unit. The product eliminates the need for transmission devices like couplings that connect joint shaft and rotary encoder, achieving downsizing/lightweighting of robot joint. As magnetic encoders have excellent environmental resistance for dust and oil, it can demonstrate its high-resolution detection in such usage conditions.

As the product integrates bearing and magnetic type encoder, it eliminates the operation for mounting and setting up rotary encoders and couplings, making assembly of robot easier. Dimensions and load capacity of the bearing in the product are the same as those of conventional bearings, and can be applied to a wide range of robots.

NTN will propose this product to robot manufacturers as a product that supports the market expansion and diversification of robots, while also expanding robot-related module area outlined in the Medium-term Management Plan “DRIVE NTN100” Phase 2. NTN will exhibit this product at “JIMTOF2022 the 31st Japan International Machine Tool Fair” held from November 8 to 13 of this year.

-

Press release on April 26, 2017:

Development of “Thin Type High Precision Angle Sensor”

(New name: “Multi Track Magnetic Ring”)

https://www.ntnglobal.com/en/news/new_products/news201700034.html

Press release on July 17, 2018:

NTN to Begin Mass-production of Newly Developed Axial Type “Multi Track Magnetic Ring”

https://www.ntnglobal.com/en/news/new_products/news201800072.html - Integrated Rotation Sensor Bearings (Cat. No. 3032/E)

https://www.ntnglobal.com/en/products/catalog/en/3032/index.html

Features

| 1 | Detect rotational speed, direction, and absolute angle while supporting rotating shaft of robot joints |

|---|---|

| 2 | Mount magnetic encoder with excellent environmental resistance |

| 3 | Contribute to downsizing and lightweighting of robot joints |

| 4 | Reduce man-hours in the process of assembly and setup of robots |

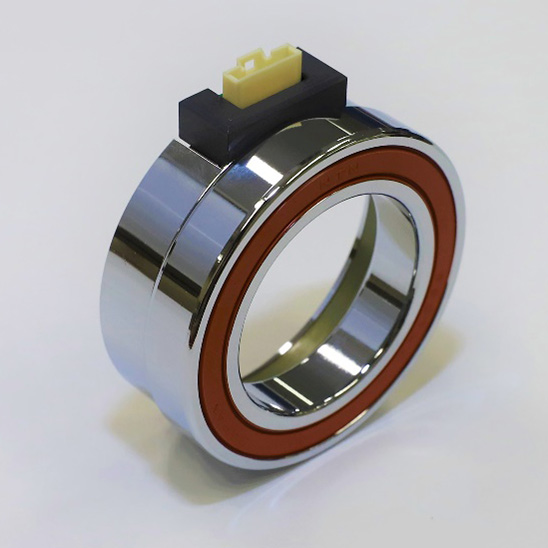

Product photo

Dimensions: Inner diameter φ35mm

× outer diameter φ55mm

× width 20.5mm