NTN Expands Insulated Bearings MEGAOHM™ SeriesOctober 25, 2021

Add “Ceramic Insulated Bearing” for Railway Rolling Stock Journal Applications, contributing to reduction of maintenance cost

NTN Corporation (hereafter NTN) has newly added “Ceramic Insulated Bearing” for Railway Rolling Stock Journal Applications (double row tapered roller bearing) to the Insulated Bearings MEGAOHM™ Series, which prevents electrical pitting*. With MEGAOHM™ Series, NTN will respond to the demand to prevent electrical pitting, which is assumed to increase in the future. MEGAOHM™ Series for traction motors in railway rolling stocks, which NTN has already been supplying, and newly added“Ceramic Insulated Bearing” for Railway Rolling Stock Journal Applications, is expected to reduce maintenance costs of customers.

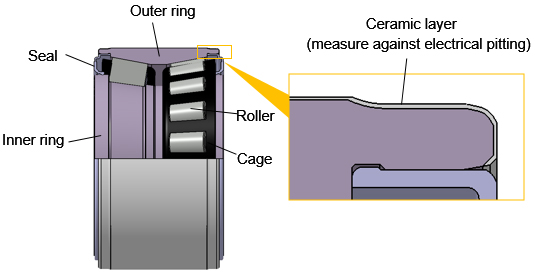

Electrical pitting, due to current leakage in bearings used in applications such as motors and generators, causes shorter bearing operating life. NTN's Insulated Bearings MEGAOHM™ Series prevents electrical pitting by blocking the passage of electric current to the bearing with the insulating layer of ceramic or resin on the width and outer surface of outer ring. Customers can select a suitable type from a wide range of material and specification of insulating layer, with features such as high voltage resistance and shock immunity. NTN has been supplying this series for traction motors in railway rolling stocks over the years.

Double row taper roller bearings for journal applications have larger outer rings than deep groove ball bearings and cylindrical roller bearings for traction motors. In order to prevent electrical pitting in the double row tapered roller bearings, it was a challenge to form uniform and wide area of ceramic layers because the ceramic layer is hard and difficult to manufacture. However, NTN succeeded to manufacture “Ceramic Insulated Bearing” for Journal applications (double row tapered roller bearing) by utilizing the technologies of thermal spraying and grinding for ceramic layers that we have knowledge from manufacturing MEGAOHM™ Series over many years. The developed product is compatible with operating conditions that involve vibration and impact peculiar to journal bearings of railway rolling stocks. It has already been adopted by a certain customer.

Currently, railway rolling stocks are attracting attention as a form of transportation with low CO2 emissions. The electrified network of railway rolling stocks is expanding around the world, and hybrid models, which combine an internal combustion engine (diesel) with traction motors and batteries, are also increasing. In urban areas in some emerging countries, the development of railway networks is also underway to reduce traffic jams. Under such situations, further measures to prevent electric pitting of bearings for railway rolling stocks is increasingly to be required. NTN globally proposes MEGAOHM™ Series including the developed products to reduce maintenance costs for railway rolling stocks by preventing electrical pitting while contributing to the security and safety of equipment requiring measures against electrical pitting.

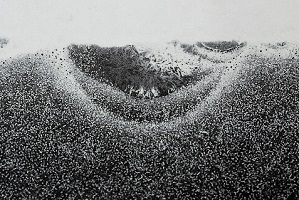

* Phenomenon in which the area where sparks occur is partially heated, causing fusion of metallographic composition. It leads to damage such as flaking of the bearing raceway and rolling surfaces.

Features of MEGAOHM™ Series

| Prevention of electrical pitting |

Insulation performance (100MΩ or more (DC500V)) The most suitable type can be selected from many variations such as insulating layer materials (ceramic or resin), voltage resistance, and shock immunity |

|---|

Applications of MEGAOHM™ Series

Railway rolling stocks (traction motors, journal applications), motors, generators, etc.

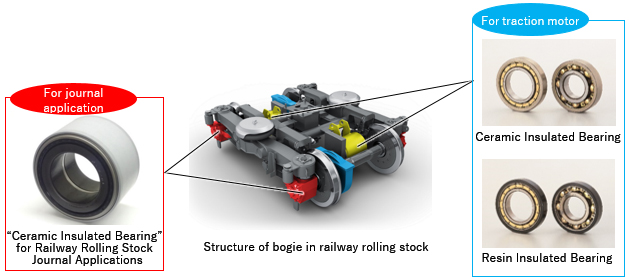

Applied parts (Railway rolling stock)

Structure of “Ceramic Insulated Bearing” for Railway Rolling Stock Journal Applications

Reference: mechanism of electrical pitting

When electric current flows to the internals of bearings, sparks can occur. Sparks may cause fusion and small holes on the surface. The part heated by sparks changes its metallographic composition and hardness in comparison with the non affected part, resulting in peeling. If electrical pitting develops further, corrugated pattern can be generated on the raceway surface of the bearing, which causes abnormal noise and vibration, leading to lost of function of the bearing.

Cross-sectional view of rollers of bearings where metallographic composition is fused by sparks

Cross-sectional view of rollers of bearings where metallographic composition is fused by sparks

Inner ring of bearing with developed electrical pitting

Inner ring of bearing with developed electrical pitting