Development of “Low Torque Plastic Bearing” for Automotive Electric Water PumpAugust 18, 2021

Contribute to low fuel consumption of automobiles by reducing torque by 30% compared to conventional product

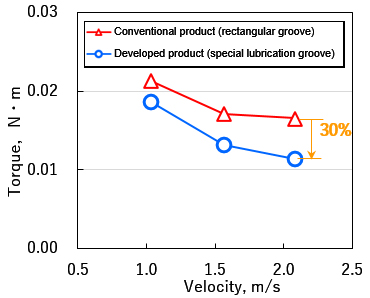

NTN Corporation (hereafter, NTN) has developed the “Low Torque Plastic Bearing” for electric water pumps of cooling systems in HEVs, EVs and FCVs. It reduces torque by 30% compared to the conventional product with the special lubrication grooves on the thrust surface of the bearing.

Background of Development

In recent years, thermal management of automotive components such as engines, inverters, batteries, and motors has become a critical issue for the electrification and low fuel consumption of automobiles. To circulate cooling water, electric vehicles are equipped with several electric water pumps per vehicle, and impellers within the pump play roles to push cooling water.

Sliding bearings such as plastic bearings using PPS resin*1 and carbon bearings are used in impellers of electric water pumps, and both bearings feature compact, lightweight, and chemical resistant. In order to improve fuel efficiency, both bearings are required to reduce torque.

- Abbreviation for Poly Phenylene Sulfide. It is a thermoplastics capable of injection molding and continuously operated at 240°C. It has excellent heat resistance, chemical resistance, and electrical insulation.

The Features

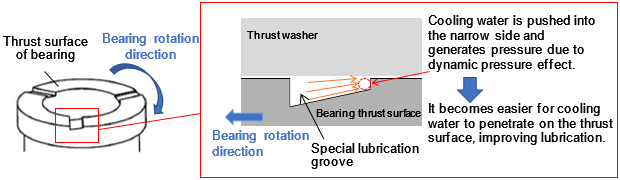

The newly developed “Low Torque Plastic Bearing” adopts NTN's PPS resin material and forms special lubrication grooves on the thrust surface. Through NTN's proprietary blend of solid lubricant and other materials, the PPS resin of this product has excellent performance of low friction and low wear properties underwater. While grooves for lubrication of the conventional product was rectangular, the special lubrication grooves of the developed product has a slope which is gradually shallowed in the counterrotating direction of the bearing. When the bearing rotates, the cooling water in the groove is pushed toward counterrotating direction. Then pressure is generated due to dynamic pressure effect, making it easier for cooling water to enter the contact areas on the thrust surface of the bearing. With these developments, NTN succeeded in reducing torque by 30% while maintaining a durability equal to or higher than that of conventional product.

The developed product has excellent wear resistance underwater without fear of cracks that is easily occurred in carbon bearings. Additionally, as the developed product can also be replaced from carbon bearings, we expect further sales expansion of this product for electric water pumps.

[Structure of special lubrication groove]

As the PPS resin of the developed product has excellent chemical resistance, it can be used not only in cooling water but also in various liquids such as solvents. In addition to automobiles, it can also be used for ZEH*2 compatible residential facilities: natural refrigerant heat pump water heaters and electric water pumps for circulation and cooling such as residential fuel cell cogeneration systems, contributing to saving energy.

NTN will propose the developed product which contributes to energy saving of electric water pumps to automotive component manufacturers and housing facility manufacturers, and contribute to reduction of CO2 emissions through electrification of automobiles and saving energy of other facilities.

- Abbreviation for Net Zero Energy House. It is a house that uses renewable energy to reduce energy consumption to zero. The house is designed to achieve a substantial saving energy by improving the thermal insulation of the outer shell and using higher efficiency facilities.

Features

Compared to the conventional product with rectangular grooves on the thrust surface

| 1. Low torque | Reduce by 30% |

|---|---|

| 2. Durability | Equivalent or higher Adopting NTN's PPS resin material that has excellent performance of low wear properties underwater |

Application

- Electric water pump for HEV, EV and FCV

- Electric water pumps for residential facilities (natural refrigerant heat pump water heaters, fuel cell cogeneration systems)

Inquiries about this release

Product photo

Comparison of torque between conventional product and developed product

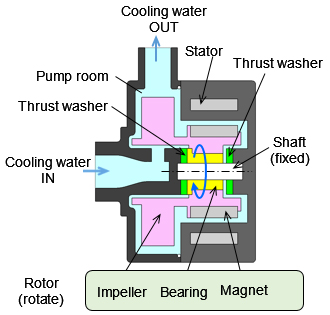

Reference: Structure of electric water pump

Cross-sectional image of electric water pump

Cross-sectional image of electric water pump

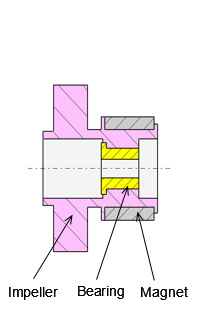

Cross-sectional image of rotor

Cross-sectional image of rotor

[Structure of electric water pump]

- Rotor integrated with impeller, bearing and magnet is installed in pump room.

- Rotor rotates due to magnetic field generated by energization of stator placed opposite to magnet.

- Impeller using the rotation transfers cooling water into the pump room.

- Axial load and radial load are generated. Thrust surface of bearing slides with thrust washer (left side in the figure). Inner diameter slides with shaft.