Development of “Low Temperature Rise and Low Torque Tapered Roller Bearing”October 20, 2020

World's highest level in low temperature rise and low torque to meet needs of next-generation mobility market

NTN Corporation (hereafter, NTN) has developed the “Low Temperature Rise and Low Torque Tapered Roller Bearing” for transmissions and differentials of automobiles. By adopting the newly developed plastic cage and optimizing the internal bearing design, it achieves the world's highest level in low temperature rise (capability for protection against seizing) and low torque performance.

Background of development

Power transmission devices such as transmissions and differentials are becoming smaller and lighter due to fuel efficiency saving of automobiles following the environmental regulations. With these changes, the usage conditions of tapered roller bearings for the devices are becoming increasingly severe. NTN released the “ULTAGE *1 Tapered Roller Bearing for Automotive Application*2” with the concept of realizing the world's highest level in high load capacity (long operating life) and permitted rotational speed in 2017 to respond to these changes in market demand.

In recent years, automotive industry is facing major changes such as transition to smart mobility and CASE. Electrification of automobiles and extension of cruising range by car sharing require high efficiency of power transmission devices. The amount of lubricating oil in the device is decreased and the oil is switched to lower viscosity oil. Bearings for such devices need to adapt to such severe lubrication conditions as well as further torque reduction.

The newly developed “Low Temperature Rise and Low Torque Tapered Roller Bearing” meets these emerging needs of the next-generation mobility markets.

- ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the “ULTIMATE” performance on any type of “STAGE.”

- Press release on May 18, 2017:

Development of “ULTAGE Tapered Roller Bearing for Automotive Application”

https://www.ntnglobal.com/en/news/new_products/news201700039.html

Features

1. Low temperature rise: 10 times*3 improvement compared to the standard type*4(world's highest level)

-Suppress temperature rise even under severe lubrication conditions due to decreasing the amount of lubricating oil and use of low viscosity oil-

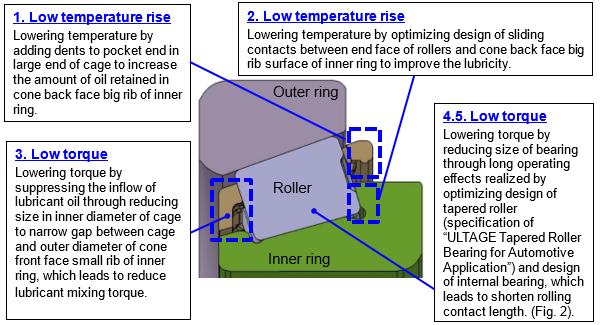

- The concave shape applied to the new plastic cage realizes oil supply to end face of rollers when there is insufficient lubrication to reduce temperature rise. (Fig.1-1)

- Design to improve the lubricity of the sliding contacts between end face of rollers and cone back face big rib surface of inner ring suppresses the temperature rise. (Fig.2-2)

2. Low torque: 66% less compared to the standard type (world's highest standard)

- Respond to needs for further higher efficiency in power transmission devices-

- New plastic cage suppresses excessive lubricant oil inflow into the bearing to reduce rotational torque due to lubricant mixing torque. (Fig.1-3)

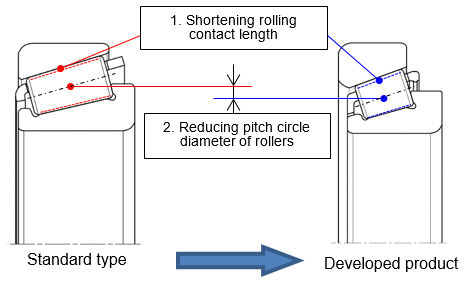

- Long operating life effect, realized by adopting roller design of the “ULTAGE Tapered Roller Bearing for Automotive Application” and optimizing internal bearing design, leads to reduce the bearing size. Rolling contact length between rolling elements (rollers) and raceway (inner and outer rings) becomes short so that rotational torque is reduced. (Fig.1-4 and Fig.2-1)

- Reduction in size of bearings also leads to reduce pitch circle diameter of rolling elements (rollers). It enables to reduce the peripheral speed between rolling elements and raceway (inner and outer rings), which leads to reduce rolling resistance so that the rotational torque is reduced. (Fig.1-5 and Fig.2-2)

- Evaluated from time of temperature in outer ring rising from normal temperature to 100°C under no-lubrication operation, assuming situations of the use of low viscosity oil in power transmission devices and sudden acceleration by electric vehicles when the amount of oil is not enough.

- NTN's standard tapered roller bearing described in “Ball and Roller Bearings Catalog” published in 2020

https://www.ntnglobal.com/en/products/catalog/en/2203/index.html

Fig1. Cross-sectional view and features of the developed product

Fig1. Cross-sectional view and features of the developed product

Fig2. Comparison between standard type and developed product

Fig2. Comparison between standard type and developed product

(showing the optimization of internal design)

Future outlook

This product realizes the features described above in compact bearing sizes so that it contributes to improvement in driving comfort through reducing the size and weight of the devices and expanding the vehicle interior space, as well as contributes to higher efficiency of power transmission devices and saving fuel / electricity efficiency automobiles. NTN will propose this product and its elemental technologies globally as specifications applicable for next-generation mobility.

NTN will continue to contribute to the realization of a smooth smart mobility society through providing products that solve various automotive issues.

Product photo

“Low Temperature Rise and Low Torque Tapered Roller Bearing”

“Low Temperature Rise and Low Torque Tapered Roller Bearing”

Applications

Power transmission devices such as transmissions (including EV and HV) and differentials