Development of “ETFA Bearing” Realizing Long operating Life with Special Heat Treatment TechnologyOctober 12, 2020

Product for construction and mining machinery, realize longer operating life than six times of standard product under debris-contaminated conditions

NTN Corporation (hereafter, NTN) has newly developed “ETFA Bearing,”*1 the tapered roller bearing for application which operates in harsh environment such as construction and mining machinery. Using a special heat treatment technology to enhance the resistance to contamination, we have achieved a longer operating life than six times of our standard bearings under debris-contaminated conditions.

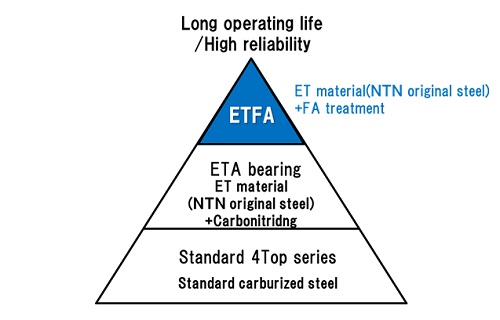

Construction and mining machineries are used in harsh environment where strong impacts and vibrations occur during the operation and at the same time foreign objects gets inside the bearing. NTN has developed standard product “4Top” series of tapered roller bearings using carburized steel, as well as the “ETA Bearing” *2, which has longer operating life by changing materials and heat treatment processing, for use in construction and mining machinery with such harsh environment. However, with the increase of the use of IoT technology, the construction machinery in recent years has been required to improve the reliability of unmanned operating vehicles and reduce life cycle costs. Due to this trend, bearings are also required to have a longer operating life, more compact in size and high-load capacity in order to make the machinery more compact.

NTN has applied newly developed heat treatment process (ETFA treatment) on the carburized steel, and confirmed that the newly developed “ETFA Bearing” has the operating life 6 times longer or more than that of standard product and 2 times longer than that of “ETA Bearings” under debris-contaminated conditions. We also verified that the product has sufficiently long operating life to the basic rating life*3 under clean condition. The ETFA treatment is the technology applying NTN's special heat treatment (FA treatment*4) technology for bearing steel on carburized steel. By improving and strengthening heat treatment requirements and its control, it maintains a moderately dispersed carbides and retained austenite and the prior austenite grains are further refined similar to ETA Bearings. As a result, we achieved both long operating life and high-robustness (resistance to foreign objects). This product also contributes to downsize the machinery because the product can have a long operating life maintaining smaller size.

NTN will propose and sell this developed product globally to further improve the reliability of construction and mining machinery and reduce life cycle costs.

- ETFA: ET material (NTN-original material) + FA process

- Long-Life AS Series TAB/ETA Bearings:

https://www.ntnglobal.com/en/products/catalog/en/3025/index.html - Undamaged even it rotated for 10,000 hours and stopped the test. Basic rating life is 243 hours

- FA (Fine Austenite Strengthening) treatment: a special heat treatment process in which NTNs are the first in the world to refine the prior austenite grains of bearing steels to 1/2 size or less (average grain size: 5µm or less). A technique to making bearings have long operating life by conducting second quenching on carbonitrided structure at low temperature.

Features

| Long operating life: under debris-contaminated conditions |

6 times longer than that of standard type (4 Top-series) 2 times longer than that of ETA bearing |

|---|

Application

General industrial machinery for construction and mining machinery, etc.

Inquiries about this release

Product photo

Examples of dimensions: φ30×φ62×17.25mm(various sizes available)

Examples of dimensions: φ30×φ62×17.25mm(various sizes available)

Product Lineup

Long operating life using special heat treatment, etc.

Long operating life using special heat treatment, etc.