NTN Releases Compact Type of “Multi Track Magnetic Ring” SeriesSeptember 2, 2020

Thin and lightweight, high-precision angle detection, applicable for more compact motor.

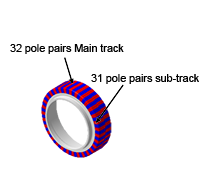

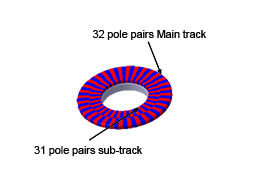

NTN Corporation (hereafter, NTN) has newly released “32/31 pole pairs series,” a compact type of “Multi Track Magnetic Ring”, which is thin, lightweight and can contribute to make a high-precision angular sensing system.

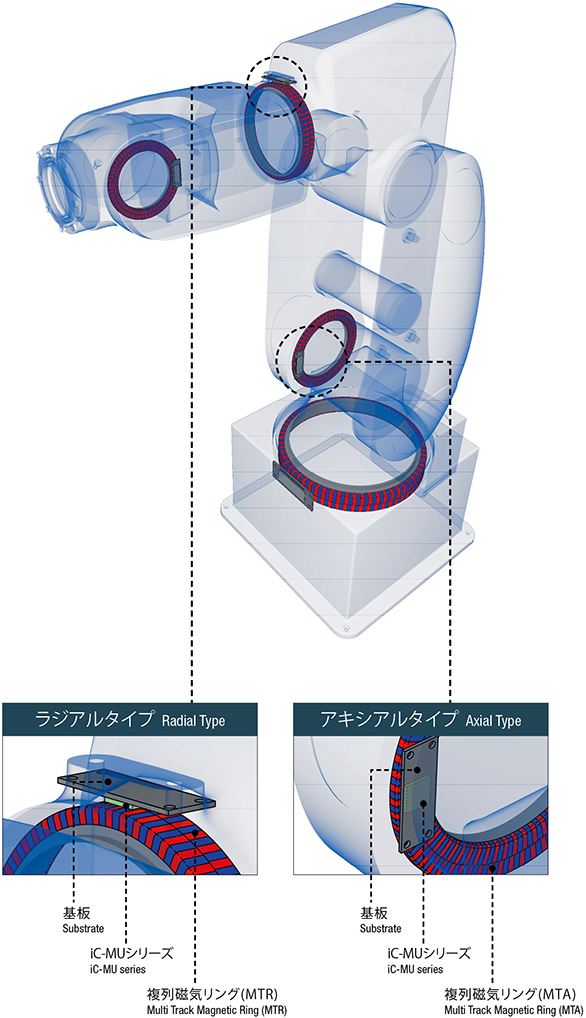

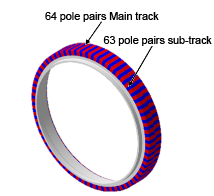

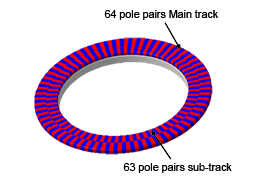

The radial type and axial type of “Multi Track Magnetic Ring” (64/63 pole pairs series) *1, which was launched in 2018, has been well received by many customers for its performance to detect the angular position of rotational devices such as robot joints and motors, taking advantage of its thin, lightweight, high-precision, and hollow (large bore) features.

As manufacturing sites becomes increasingly automated, we have been proposing the “Multi Track Magnetic Ring” for a wide range of application expanding its demand such as motors, industrial robots and collaborative robots. With high demand for downsizing of the product, we have newly developed the “32/31 pole pairs series.”

The “32/31 pole pairs series” uses magnetization technologies of 64/63 pole pairs series to magnetize in double track, 32 pole pairs on the main track and 31 pole pairs on the sub track. With this technology, we achieved a dramatic reduction in size and weight while maintaining high-angle-detection accuracy. Compared with the 64/63 pole pairs series, outer diameter is reduced in size to approximately 1/2, and its weight is also reduced to approximately 1/2 that of the existing product (32/31 pole pairs). Combined with a dedicated magnetic sensor IC*2, it enables advanced angular sensing of maximum 19 bits (resolution of approx. 0.00068°). Comparing with the conventional series, it is also excellent in environment resistance to vibrations, high temperatures, dust, oil mist, etc.

Furthermore, in addition to the compact size, the magnetic pole pitch *31.5 mm and 2.0 mm specifications (1.28 mm specifications for the current product) have been newly added, and customers can select from a wider range of sizes and specifications.

As robotization and automation are accelerating in all industries, NTN are strengthening our robot-related and sensing businesses as one of our new business areas. We will continue to expand the product lineup of this series in order to respond to customer needs and further expand our business.

- NTN to Begin Mass-production of Newly Developed Axial Type “Multi Track Magnetic Ring” Products

https://www.ntnglobal.com/en/news/new_products/news201800072.html - Magnetic sensor IC that can be combined with Multi Track Magnetic Ring: iC-MU of iC-Haus GmbH (German)

https://www.ichaus.de/product/iC-MU - Length between the N and S poles of magnetic

Product features

| 1. | Resolution: Maximum. 19bit (resolution of approx. 0.00068°) |

|---|---|

| 2. | Thin, lightweight, hollow (large bore) shape |

| 3. | Magnetic type advantage that provides excellent environment resistance to vibrations, high temperatures, dust, oil mist, etc. |

| 4. | Allows absolute angle detection |

Application

Angle detection of various robot joints, motors, gearboxes, power tools, etc.

Multi Track Magnetic Ring Catalogue

https://www.ntnglobal.com/en/products/catalog/en/6512/index.html

Inquiries about this release

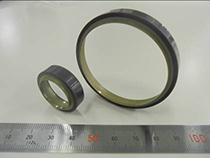

Product Photo

Radial type

Radial type

(Right: 64/63 pole pairs series)

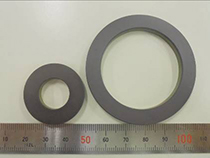

Axial type

Axial type

(Right: 64/63 pole pairs series)

Specifications

| Radial type | |

|---|---|

| 32 pole pairs | 64 pole pairs |

Outer diameter: φ25.5mm

Bore diameter: φ18mm

Axial width: 8.2mm

Weight: 4.6g

|

Outer diameter: φ51.5mm

Inner diameter: φ44mm

Axial width: 8.2mm

Weight: 10.7g

|

| Axial type | |

|---|---|

| 32 pole pairs | 64 pole pairs |

Outer diameter: φ30mm

Bore diameter: φ15mm

Axial width: 4mm

Weight: 4.4g

|

Outer diameter: φ56mm

Inner diameter: φ41mm

Axial width: 4mm

Weight: 9.8g

|

Example of applications

Angle Detection of Robot Joint