Development of a System Together with Air Water Inc. that Can Clean Complex Shapes with High EfficiencyApril 13, 2017

Collaboration with Dry Ice Snow Precision Cleaning System and Parallel Link High Speed Angle Control Equipment

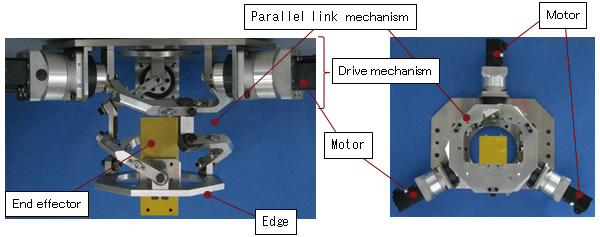

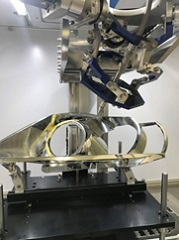

Air Water Inc. (hereafter, Air Water) and NTN Corporation (hereafter, NTN) have developed a new product by combining the technology of the Dry Ice Snow Precision Cleaning System (hereafter, QuickSnow®) which uses liquid carbon dioxide from Air Water and the technology of the Parallel Link High Speed Angle Control Equipment* from NTN. Incorporating the QuickSnow® onto NTN's Parallel Link High Speed Angle Control Equipment has the feature of allowing high efficiency cleaning without damaging even complex shapes while smoothly and quickly controling the nozzle direction.

QuickSnow® is a dry cleaning system that cleans microscopic foreign substances by causing dry ice fine particles generated from liquid carbon dioxide to collide with the object targeted for cleaning at high speed. In order to maximize the cleaning effect of QuickSnow® it is necessary to move the spray nozzle to the appropriate position while cleaning. However, there were issues in achieving smooth nozzle movement when combining it with conventional vertical multi-joint robots.

The developed product realizes the extreme removal of foreign substances, which were difficult to remove in the past and QuickSnow® was unable to fully effect, by using Parallel Link High Speed Angle Control Equipment to control the direction of the nozzle on QuickSnow® while operating continuously, and it is able to effectively clean microscopic foreign substances of a 1/1000 mm size. Furthermore, the QuickSnow® nozzle incorporated inside the Parallel Link High Speed Angle Control Equipment enables high speed operation along with contributing towards making the equipment compact because the required wiring can also be incorporated inside the structure.

The introduction of the developed product will be proposed to production process that requires highly efficient precision cleaning such as automobile parts, semiconductor device and electronic component, and aim to achieve precision cleaning that was once difficult using conventional cleaning equipment.

This developed product was shown as a reference exhibit by Air Water at the 27th Finetech Japan Exhibition to be held from April 5th to 7th, 2017.

* Press release dated November 7, 2014 “Enhancements to the ‘Parallel Link High Speed Angle Control Equipment’ for High-speed, High-precision Positioning”

https://www.ntnglobal.com/en/news/new_products/news201400104.html

Features

| (1) | Achieves high performance dry cleaning with very smooth nozzle movement |

|---|---|

| (2) | No risk of chemical contamination, water mark or liquid surface tension damage to the object |

| (3) | Provides high productivity (reduced cycle time, reduced setup time) |

| (4) | Improves maintenance (compact wire routing) |

Application

Precision cleaning of complexly shaped parts such as automobile parts, semiconductor and electronic components.

Inquiries about this release

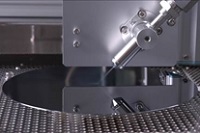

Dry Ice Snow Precision Cleaning System

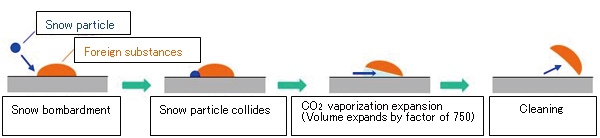

The Dry Ice Snow (CO2 snow) Cleaning System is a dry cleaning method that removes organic residue and particles on precision components and substrate surfaces by colliding dry ice fine particles created from liquid carbon dioxide with the object targeted for cleaning at high speed.

(Principle)

Parallel Link High Speed Angle Control Equipment

QuickSnow® Cleaning System incorporated with the Parallel Link High Speed Angle Control Equipment

|

|