Development of “ULTAGE Spherical Roller Bearing with Compact Seal” for Mining Transport ConveyorsJuly 1, 2016

Longer operating life and the world's highest standard high load capacity, and easier to use

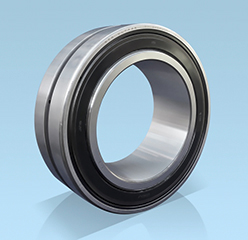

NTN Corporation (hereafter, NTN) has developed*1 the “ULTAGE*2 Spherical Roller Bearing with Compact Seal” for transport conveyors used in the mining industry. The developed bearings feature a longer operating life by preventing the ingress of foreign matter under harsh environments, and delivers the world's highest standard high-load capacity, as well as enhancing the accuracy and ease of installation and making it easier to use.

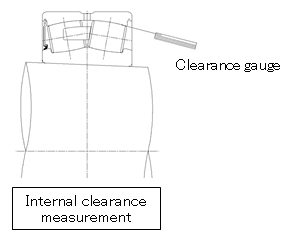

Spherical roller bearings used in mining transport conveyors need to have a high load capacity as well as measures to prevent foreign matter as they are used outdoors, in dusty areas or other harsh environments. To overcome this, there is an increasing demand for bearings with a seal between the outer and inner rings. Yet including a seal while retaining the same boundary dimensions as standard type bearings requires the dimensions of the peripheral components to be changed due to the added thickness of the seal. The presence of the seal prevents measurements of the bearing clearance during installation, with incorrect positioning as one of the possible reasons for the shorter service life of such bearings.

The developed product, with a special, compact seal and optimizations realize the internal bearing design to be the world's highest standard high-load capacity as a sealed spherical roller bearing, while retaining the same dimensions as the standard type bearing. The use of a removable seal not only ensures reliable sealing, but also allows accurate adjustments of the clearance during installation. No changes are required to the size of the peripheral components as the dimensions are the same as standard type bearings.

NTN will propose the developed product as a replacement for standard type bearings that is effective for preventing the ingress of foreign matter, and market it mainly for mining equipment where there is higher demand.

- The 23134 to 23192 developed as a series (outer diameter: φ280 to φ760 mm)

- ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the “ULTIMATE” performance on any type of “STAGE.”

Features

| (1) Fully compatible with standard type bearings |

|

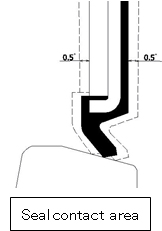

Same dimensions as standard type bearings(without seal), making replacement possible without changing the peripheral components dimensions Same 0.5° allowable aligning angle as standard type bearings |

|---|---|---|

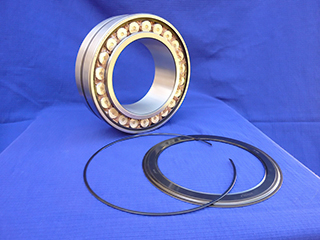

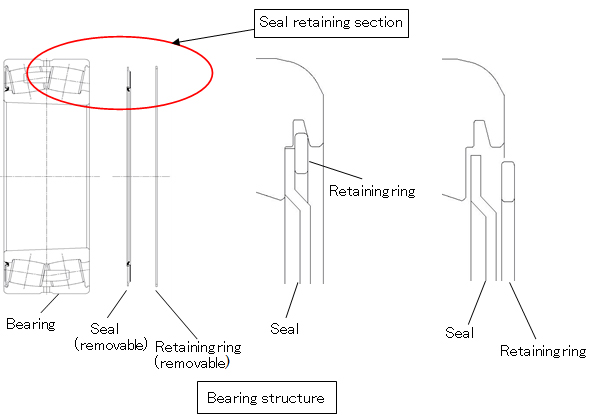

| (2) Use of removable seal |

|

Seals can be removed as they are held in place with a retaining ring A structure to prevent seals coming off due to bearing self-alignment when handling |

|

Allows accurate adjustments of radial internal clearance during installation of bearing | |

| (3) Special thin seals used for compact bearing design |

|

Equalize contact pressure along the seal lip to suit bearing self-alignment, to prevent ingress of foreign matter, and reliable sealing |

|

Achieves the world's highest standard load capacity as sealed spherical roller bearings by use of compact seals |

Applications

Mining transport conveyors

Inquiries about this release

Product photo

|

|

Structure

|

|

|

|