Development of the “Electric Motor and Actuator” SeriesJune 21, 2016

Smart electric actuator applicable to onboard components

NTN Corporation (hereafter, NTN) has developed the highly versatile “Electric Motor and Actuator” series which is essential for by-wire* control that is expected to be used more in the future for vehicle drive and control.

There is growing demand for automated driving and better fuel efficiency throughout the automotive industry in recent years, with electrification and by-wire control in particular being developed at a rapid pace as various systems are used more for drive and control.

To address such market trends, NTN has combined its core technologies of bearings and ball screw product technology with motor design technology and electrical control technology for controlling vehicles to develop the “Electric Motor and Actuator” series. The product lineup features common components and specifications, and available with variations in shape and size, which eliminates the need for individual designs for a shorter development time.

The newly developed product series can be used for various onboard applications, with the aim of increasing the range of applications beyond vehicles. NTN first aims to begin mass-production of the series soon and move forward with global sales efforts for onboard vehicle applications, as well as expanding applications to other equipment that utilize actuators.

NTN exhibited the developed series at the “Automotive Engineering Exposition 2016” which was held at Pacifico Yokohama from May 25 to 27.

* By-wire:

A system such as brake-by-wire and shift-by-wire, where driver operations are converted from mechanical systems to electrical signals, to drive actuators.

Features

- Available with three types of motor shaft configurations to suit applications: “Coaxial Shaft Type,” “Coaxial Hollow Shaft Type” and “Parallel Shaft Type”

- Available in three sizes: small, medium and large. The medium series in particular is expected to have a high level of demand, and available with a greater range of options

| (1) Coaxial type |

|

|---|---|

| (2) Parallel shaft type |

|

Inquiries about this release

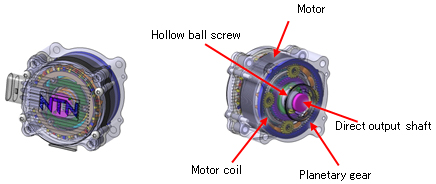

Product photo and structural drawing

Coaxial Hollow Type |

|

|

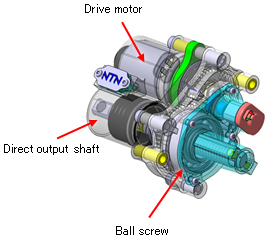

Parallel Shaft Type |

|

|

Example of applications

Electric motors and actuators for onboard automobile and motorcycle applications

- Small series: various electric valves, electric throttles and other applications for engines

- Medium, large series: clutches, shifters, brakes, electric pumps and other applications