Development of “ULTAGE Spherical Roller Bearing EMA Type”June 1, 2015

[World's highest standard high-load capacity and outstanding vibration resistance and impact load performance]

NTN Corporation (hereafter, NTN) has developed the “ULTAGE*1 Spherical Roller Bearing EMA Type” that delivers the world's highest standard of high-load capacity and outstanding vibration resistance and impact load performance with optimizations made to the internal bearing design.

Mining equipment used for extracting underground resources such as iron ore and coal operate under conditions involving vibrations and impacts, and widely use spherical roller bearings for their self-aligning design.*2 Breakers and vibrating sieves*3 in particular are used under extremely tough conditions, and NTN developed the “UA Series” lineup with resistance against vibration and impact loads to contribute long-term reliable operation. Yet with the increase in mining in recent years mainly in emerging markets, long-term and reliable operation of mining equipment is required, and the bearings used need an even higher level of performance and reliability.

The newly developed “ULTAGE Spherical Roller Bearing EMA Type” features an optimized internal bearing design to maximize the size and number of rollers of the rolling element. These improvements increase the basic dynamic load rating by up to 20% compared to the conventional spherical roller bearing UA type to achieve the world's highest standard high-load capacity. The structure of the retainer has also been reviewed and the use of a high-strength machined retainer to improve retainer strength by up to 55%*4 to achieve an outstanding level of resistance against vibrations and impact load performance. The increase in bearing heat has also been reduced by up to 10% to further improve rotational precision. Special heat treatment has also been used for 200°C heat-resistant specifications to achieve dimensional stability and a long operating life under high temperature environments.

NTN will develop lineup of 13 models ranging from 170mm to 420mm bearing outer diameter, and release the lineup globally.

- ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the “ULTIMATE” performance on any type of “STAGE.”

- Adjusting the inclination of the outer ring against the ring or the inner ring central shaft enables mounting errors to be tolerated.

- A vibration-generating machine that vibrates the sieve surface in both circular and linear directions to sieve the material.

- Comparison of the retainer itself

Features

Compared to the conventional product (Spherical Roller Bearing UA Type)

| (1) World's highest standard high-load capacity | Basic dynamic load rating: up to 20% increase |

|---|---|

| (2) Outstanding vibration suppression and impact load performance | Retainer strength: up to 55% increase |

| (3) Low heat generation | Up to 10% reduction in bearing heat increase under vibration and impact load conditions |

| (4) 200°C heat-resistant specification | Special heat treatment used for dimensional stability and long operating life under high temperature environments |

Application

Breakers, crushers, vibrating sieves, reducers

Inquiries about this release

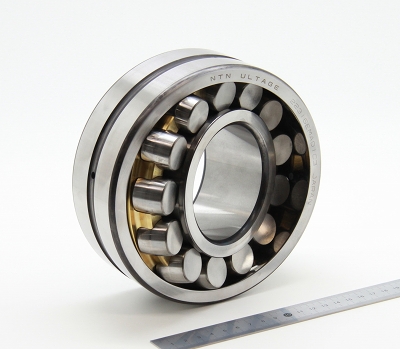

Product photo

Example of main dimensions: φ80 × φ170 × 58mm (photo is when the bearing is opened)