Development of “High Load Capacity Cylindrical Roller Bearings” with Rolling Element SeparatorSeptember 4, 2013

[World's highest level of load capacity and high-speed rotating performance, as well as longer operating life!]

NTN Corporation (hereafter, NTN) has developed the High Load Capacity Cylindrical Roller Bearings that takes both load capacity and high-speed rotating performance to new levels.

Cylindrical roller bearings have a greater load capacity than ball bearings, and are primarily used in industrial gearboxes and reducers that are subjected to relatively high loads. Even cylindrical roller bearings feature “full complement roller bearings” without retainers for load capacities that are particularly high. Full complement roller bearings can use a larger number of rollers compared to ordinary bearings with a retainer, which extends the rated life. Yet the lack of a retainer can result in adjacent rolling elements coming into contact with one another when rotating at high speeds, causing scoring*1, smearing*2 and other damage, which limits applications mainly to low speed operation

With larger devices being manufactured to increase efficiency of wind turbine gearboxes or reducers used in hydraulic construction excavators and mining dump trucks, there is an increasing need for higher load capacity, as well as high-speed rotating performance to deliver higher output and efficiency.

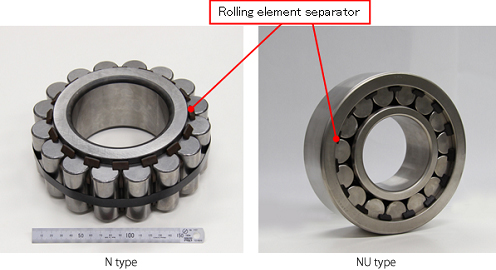

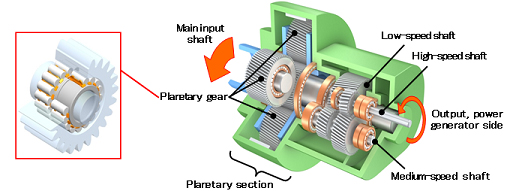

The newly developed “High Load Capacity Cylindrical Roller Bearings” uses the “rolling element separator” developed by NTN to prevent contact between rolling elements, which allows almost the same number of rolling elements as full complement roller bearings to be integrated without any loss in rolling performance, and thus achieving the world's highest level of load capacity. Featuring 1.5-times longer rated life than cylindrical roller bearings with ordinary retainers, the new bearing can be used as low-speed shafts in gearboxes and reducers, as well as applied to medium and high-speed shafts. The optimal design can be applied to rolling elements of planetary gear type gearboxes and reducers often used in wind turbines or construction machinery, which means the inside bore surface of the planetary gear can be used as the outer ring track surface (photo: N type), contributing to lighter and more compact devices.

NTN has already started proposing the product to manufacturers of wind turbines and construction machinery, and plans to continue proposing it for industrial machinery applications centered on gearboxes and reducers.

*1 Scoring:wear caused by burnt out components. Often occurs when rolling elements slide in opposite directions, or there is insufficient lubricant used.

*2 Smearing:one type of surface damage that occurs on rolling surfaces, and is a group of small burnt sections.

Features

(1) Use of a proprietary rolling element separator to achieve high load capacity and high-speed rolling performance

- Almost the same quantity of rolling elements as full complement roller bearings can be integrated

1.5-times rated life (compared to cylindrical roller bearings with retainers) - Prevents contact between rolling elements that occurs in full complement roller bearings

1.5-times high-speed rolling performance (compared to full complement roller bearings)

(2) Contributes to lighter, more compact devices

- Optimal design of rolling elements mean internal gear surfaces and rolling shafts can be used as outer ring track surfaces

Inquiries about this release

Product photo

High Load Capacity Cylindrical Roller Bearings

High Load Capacity Cylindrical Roller Bearings

Example of application

| Example configuration of planetary gear using internal gear surfaces as outer ring track surfaces | Wind turbine gearbox layout |