Development of “Ball Screw Drive Module”

(New name: “Ball Screw Drive Module for Electric Hydraulic Brake**”)April 23, 2013

[Cooperative regenerative braking system adopted to extend the driving range of EV and HEV]

NTN Corporation (hereafter, NTN) has developed “Ball Screw Drive Module” (hereafter, the module) for cooperative regenerative braking systems designed to improve the energy efficiency of electric vehicles (hereafter, EV) and hybrid vehicles (hereafter, HEV), and has started to supply mass-produced units.

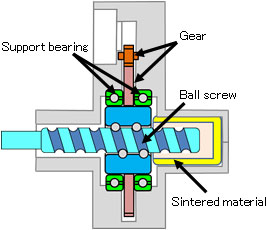

Since starting mass-production of ball screws for mechanical automatic transmission systems for large trucks, NTN has increased sales of ball screws for automobiles through development of technologies designed for long life. Compact drive module products have been developed through combinations of a high load capacity support bearings and sintered materials for ball screws. Proven mass-production ball screw technology and a simple structure help give the module a high level of reliability.

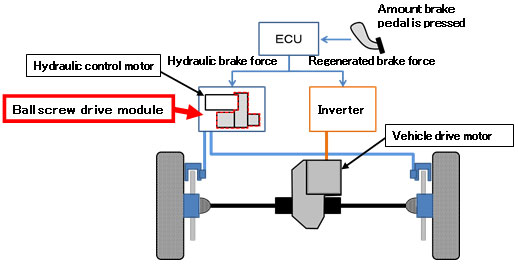

EV and HEV generate brake force by using the vehicle's drive motor as a generator while braking to convert (regenerate) the vehicle's driving energy to electrical power. Regenerating as much electrical power as possible helps to extend the driving range of the vehicle. The cooperative regenerative braking system calculates the amount of brake force required from how much the driver presses the brake pedal or from the speed of the vehicle, and determines the best way to distribute regenerated brake force from the drive motor, as well as hydraulic brake force. This new module converts rotational motion for the hydraulic control motor accurately to linear motion via a reducer gear and ball screw to control the hydraulic brake force. This allows more accurate control of hydraulic brake force, and a greater amount of driving energy to be regenerated.

NTN will propose more ball screw module products to suit increasing electrification of various drive mechanisms for automobiles, and aims to expand the EV system business even further.

| **: | The name of this product was changed to the new name of “Ball Screw Drive Module for Electric Hydraulic Brake” from April 2014. |

Features

| (1)Compact and lightweight | more compact design with the use of a high load capacity ball screw, high load support bearing and sintered materials |

|---|---|

| (2)High reliability | applies proven mass-production ball screw technology for automobiles, simple structure with minimal number of parts |

Applications

Hydraulic brake control materials of cooperative regenerative braking systems

Electrification of hydraulic actuators for automobiles and motorcycles

Inquiries about this release

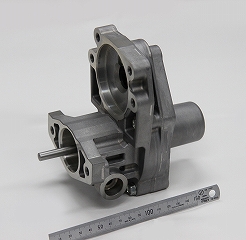

Product photo

Ball screw drive module (external photo)

Cross-sectional view

Example of application

Cooperative regenerative braking system