Development of “Self-lubricating BEARPHITE”February 26, 2013

[Sintered bearing with special graphite for dry environments, a first in the sintered metal industry]

NTN Corporation (hereafter, NTN) has developed the “Self-lubricating BEARPHITE” that can be used in environments not suited to oil. This was achieved by using special graphite and optimizing the bearing material composition.

Oil-impregnated sintered bearings that are widely used in the industrial machinery and automotive fields are lubricated with a lubricant retained within the bearing. Yet oil-impregnated sintered bearings cannot be used in certain applications where the lubricant may adhere to surrounding components and cause a reduction in performance, or hot environments where the lubricant is prone to evaporation, such as the inside of photocopiers or automobile headlights.

The newly developed “Self-lubricating BEARPHITE” is a bearing that uses special graphite as a solid lubricant, the first time in the sintered metal industry. The bearing can be used in environments not suited to oil.

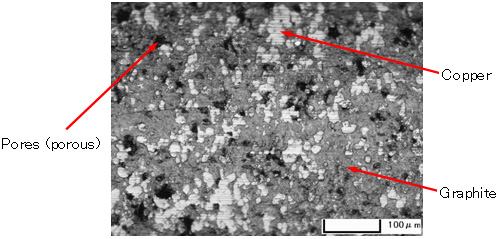

The graphite added as the solid lubricant of ordinary sintered bearings has a lower liquidity compared to other metal powders, and cannot be molded properly in large quantities. NTN changed the ratio of metal powder and increased the quantity of special high-liquidity graphite to five-fold over conventional types of graphite. This combination has resulted in a high level of productivity while also delivering outstanding sliding characteristics and wear resistance without the need for lubricating oil. The developed bearing is also conductive which allows static electricity to be released while also preventing the adhesion of dust, one of the causes of non-conforming bearings. The bearing can also operate as a material for supplying electricity, which eliminates the need for other electricity supply components and contributes to a reduction in the number of components used in devices.

NTN has already started proposing the developed product to office equipment manufacturers and automotive related manufacturers. In addition to bearings, the technology can be applied to a wide range of fields, as it can be used in composite material products with integrated resin parts, or applied to sliding materials other than bearings.

Features

Sintered bearing that can be used in dry environments

- Uses the industry's first special graphite

→ Molding flexibility for a high level of productivity - Five-fold increase in graphite quantity compared to conventional products (oil-impregnated sintered bearings)

→ Outstanding sliding characteristics

→ 1/50th or less wear (dynamic friction coefficient μ≦0.3) compared to conventional sintered materials (that do not contain oil) - Conductivity

→ Prevents dust adhering to the bearing, and reduces the amount of device components

Inquiries about this release

Product photo

Example of size: inner diameter 6 mm × outer diameter 12 mm × width 6 mm

Structure

Developed Material

Area ratio of graphite 80%

(quantity of graphite additive five-fold compared to conventional products)

Example application

- Photocopier bearings, power supply chips

- Toner cartridge magnetic roll bearings of laser printers

- Headlight sliding material