Development of “Deep Groove Ball Bearing for High Thrust Loads”November 16, 2011

[Major increase in thrust load capacity, and also suitable as replacement for tapered roller bearings!]

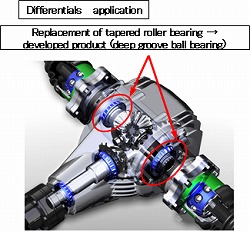

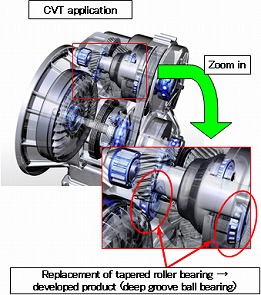

NTN Corporation (hereafter, NTN) has developed the “Deep Groove Ball Bearing for High Thrust Loads” to increase thrust load*1 capacity three-fold, and which are able to replace tapered roller bearings used in vehicle differentials*2 and transmissions.

There is currently an increased demand for reduced CO2 emissions and fuel consumption in growing markets with the increased uptake of vehicles around the world, with demand for lower torque and higher efficiency axle bearings for automobiles also on the rise. Extremely high levels of torque are transmitted through parts in the automobile drive-train, including the differential and transmission systems. One example is the high levels of force generated on the differential side (wheel side) of differential gears and the associated thrust forces that support axle bearings are subjected to. To meet these high levels of forces, tapered roller bearings are often used in general applications with high thrust loads. Yet the increased rotational torque of tapered roller bearings compared to ball bearings due to the large contact area between the rolling element and bearing ring, and complex pre-compression adjustment required for assembly have been the cause of many issues.

The “Deep Groove Ball Bearing for High Thrust Loads” developed by NTN provides an optimum shape for bearing ring grooves, and the use of a newly designed assembly cage increases the thrust load capacity of standard deep groove ball bearings three-fold. The new bearing can be used for high load applications such as automobile drive-trains.

Using this bearing to replace tapered roller bearings can reduce bearing torque 60%*3 in differential-side applications, and combined with the reduced assembly man-hour, reduce automobile CO2 emissions and fuel consumption, while also increasing customer productivity.

NTN will display the bearing at “The 42nd Tokyo Motor Show 2011”, held at Tokyo Big Sight between December 2 and 11, and plans to sell the bearing on global markets in the future.

*1:Thrust load is a load that acts in the direction of shaft rotation. Radial loads are loads that act perpendicularly to the rotating shaft.

*2:A power transmission device used in machines with wheel such as automobiles. The device absorbs the difference in speed between the inner and outer wheels when the automobile turns a corner while distributing the same amount of torque delivered from the engine.

*3:Comparison made with 2L class differential-side tapered roller bearings at 70% engine torque load and speed of 100 km/h

Features

| (1) Thrust load capacity |

three-fold increase (compared to standard deep groove ball bearings) |

|---|---|

| (2) Axle bearing rotational torque |

60% reduction (compared to tapered roller bearings) |

| (3) Reduced assembly man-hour |

eliminates need for differential-side pre-compression adjustment during assembly (compared to tapered roller bearings) |

Inquiries about this release

Product Photo

Deep groove ball bearing for high thrust loads

(bearing dimensions: φ40 × φ80 × 18)

Applicable Parts

Automobile drive-train applications