Development of 2 Types of “Elliptic Vibratory Parts Feeder” Combining High-Speed and QuietnessNovember 14, 2011

[Compatibility by Compactification (Bowl Type), and Equipped with Elliptical Vibration Mechanism (Linear Motion Type) First in the Industry]

NTN Corporation (hereafter NTN) has developed an “Elliptic Vibratory Parts Feeder” with improved speed and quietness by adopting an elliptical vibration mechanism. Two types of feeders were developed, a “Bowl Type Elliptic Vibratory Parts Feeder” compatible to the mounting size of a conventional type through a compact design, for the type which performs an automatic alignment feeding of parts, and the first “Linear Motion Type Elliptic Vibratory Parts Feeder” in the industry *1 for the type which linearly transfers aligned parts.

Common part feeders transfer and perform the alignment feeding of parts by providing a reciprocating vibration in a single direction. However, improvement in the transfer speed and the quietness, such as noise which is generated when the transferring surface and the parts make contact has been an issue. Also, a feature of the elliptical vibrating type which generates vibration by a reciprocating motion in the horizontal and vertical directions is the quietness by high-speed transfer and smooth feeding of parts; however, the complicated internal structure and expansion of the size of the equipment has been an issue in the generation of elliptical vibration.

The developed “Elliptic Vibratory Parts Feeder” realized improvements in high-speed and quietness by adjusting the amplitude and phase of the vibration in the horizontal and vertical directions, to generate an optimal elliptical vibration. In the internal structure, the compactification of the vibrator was achieved by devising the layout of the electromagnet and leaf springs which generate the vibration, and reduced the number of attachment parts, such as sensors and etc., and by providing compatibility to the mounting size of a conventional type which vibrates in a single direction, it is easy to replace a conventional type feeder, not only the introduction of a new feeder.

NTN will expand into the market for various customers in the future.

*1 In the linear motion type which uses an electromagnet and leaf springs with an elliptical vibrating mechanism.

Features

- Improved feeding capacity by high-speed transfe

- Bowl type: 12m/min (150% compared to conventional products)

- Linear motion type: 10m/min (160% compared to conventional products)

- Achieved low noise of alignment feeding

Improved quietness with smooth motion by elliptical vibration (Reduced 10% compared to conventional products) - Compatible to the mounting size of conventional feeders

Inquiries about this release

Product Photo

Comparison of Vibration with Conventional Type

Conventional Type

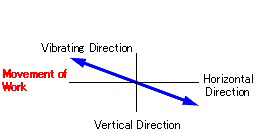

A slanted vibration is generated with a combination of the attraction force of the electromagnet in the horizontal direction, and the reaction force of the leaf spring mounted on a slant, which smoothly lifts up the work. (Simple reciprocating vibration)

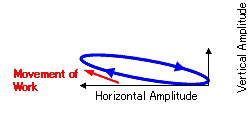

Developed Product (Elliptical Vibration Type)

An elliptical vibration is generated by simultaneous vibration of the leaf springs and the electromagnet arranged in the horizontal and vertical directions. By adjusting the size and phase of the amplitude in each direction, the angle of the elliptical vibration can be set freely, which enables transfer according to the characteristics of the work.