Development of “Monodrive Two-way Feeder with The Separation Mechanism for Tangled Springs”November 7, 2011

[Separation function for randomly entwined coil springs now integrated into a compact parts feeder!]

NTN Corporation (hereafter, NTN) has developed the space-saving “Monodrive Two-way Feeder with The Separation Mechanism for Tangled Springs”, which is also capable of reliably aligning and supplying randomly entwined coil springs.

Devices used to automatically transport randomly entwined coil springs generally consist of a parts feeders for aligning and supplying springs, and an independent spring separator for separating randomly entwined coil springs. Yet space required for the installation area of such a system had become a problem.

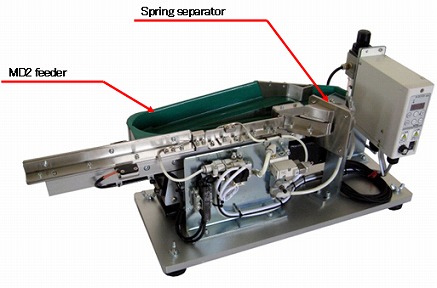

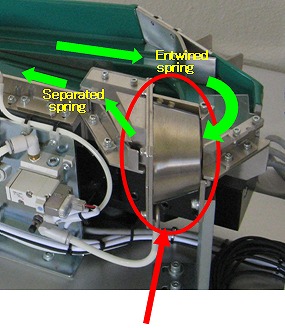

The new “Monodrive Two-way Feeder with The Separation Mechanism for Tangled Springs” features a newly developed compact spring separator integrated with the space-saving Monodrive Two-way Feeder*1 (hereafter, MD2 Feeder). The space required for installation is approximately half of that compared to using a combination of bowl-type parts feeder and an independent spring separator. The spring separator uses compressed air to circulate and separate randomly entwined springs to deliver a reliable supply of coil springs.

The newly developed product has been designed for transporting small bore coil springs (diameter 2 to 5 mm), but will be developed into a series capable of a wide range of spring sizes.

NTN is contributing to the automation and reliable operation of facilities with parts feeders by continuing to develop and propose technologies that meet the wide range of needs of customers.

The product is planned to be exhibited at the “Parts Feeder Exhibition 2011”, held at Tokyo Big Sight between November 9 and 12.

*1 February 25,2005 Press Release : Monodrive Two-Way Feeder

Features

- Space-saving: half the installation area compared to conventional products

- - Compact MD2 feeder integrating the newly developed spring separator (separation mechanism)

- Reliable supply

- - Separates randomly entwined springs quickly and accurately before supplying them

Inquiries about this release

Product Photo

Product dimensions: 600 (L) × 200 (W) × 200mm (H)

Product weight: approximately 20 kg

Spring separator