Development of “Electric Actuator for Shift-by-wire”November 7, 2011

[Major weight savings and more compact size, integrated positional sensor]

NTN Corporation (hereafter, NTN) has developed the “Electric Actuator for Shift-by-wire*1” for vehicles, aimed at achieving major weight savings and a more compact size.

In recent years, there has been a focus on electrification of vehicles with a shift from manually and hydraulically operated devices to those operated with electric drive motors, with the aim of achieving greater vehicle comfort, safety, weight savings and efficiency in order to improve fuel efficiency. Drive motors (actuator units) used in electrically operated devices have also increasingly shifted to the use of ball screws instead of slide screws and worm gears, as a means of improving the conversion efficiency of the rotational force of motors to linear or reciprocal motion.

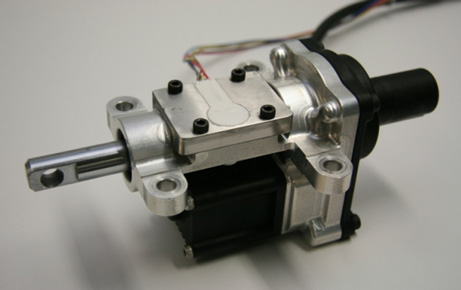

The “Electric Actuator for Shift-by-wire” developed by NTN incorporates ball screw technology that is more efficient and compact than conventional products*2, and allows increased efficiency and greater reliability for shift-by-wire. The dual shaft structure, that of the ball screw shaft and output shaft, have been reviewed and integrated into a single shaft to reduce the number of parts, decrease size and achieve major weight saves of 60% compared to conventional products. A proprietary positional sensor to detect the position of protrusions directly from the output shaft has been integrated within the compact frame, eliminating the need for a separate positional sensor or associated assembly processes.

With the increasing shift in electrically operated vehicle parts, NTN plans to market this newly developed lightweight and compact product, which incorporates high efficiency ball screw technology, to a wide range of customers into the future.

*1 A system that changes gears remotely using electric signals

*2 July 27,2009 Press Release : Electric actuator

Features

| (1) Lightweight and compact |

60% weight savings over conventional products (2.7kg → 1.1kg) |

|---|---|

| (2) Integrated positional sensor |

proprietary compact structure to detect the position of protrusions directly from the output shaft |

Application

- Electric actuator units for shift-by-wire of vehicle

- Various electric actuator units for other vehicle applications

Inquiries about this release

Product Photo

Conventional product

Developed product