Development of “Ultra Small Grinding Sludge Briquetting Machine”October 28, 2010

[zero emissions reduces environment impact; saves space and energy]

NTN Corporation (hereafter NTN) has developed an “Ultra Small Grinding Sludge Briquetting Machine (PRG-III)” with new functions for recycling grinding sludge from metallic processing at small manufacturing facilities.

NTN achieved ISO14001 certification in 1998 and began aggressive efforts to improve recycling and reduce the company's environmental impact. In 2000, NTN developed equipment capable of separate grinding sludge (generated during bearing production) into metallic briquettes and grinding coolant. This recycling technology allowed NTN to reuse the grinding by-products. As a result, the disposal cost of grinding sludge was eliminated and 100% recycling of NTN's grinding sludge was achieved.

Since that time, NTN has produced two machine sizes to match the volume of grinding sludge: PRG-I (30-ton per month capacity; 1,000kN) and PRG-II L (20-ton per month capacity; 520kN). These machines have a good reputation at NTN's customers. Since the introduction of the first two models, NTN has seen market demand from both large facilities wanting to process a small amount of waste and many smaller customers with less grinding capacity than required for either the PRG-I or PRG-II L machines. NTN has developed an “Ultra small grinding sludge briquetting machine (PRG-III)” which occupies a small space to facilitate small manufacturing plants.

This machine will first be displayed at the “25th Japan International Machine Tool Fair (JIMTOF)” held from October 28 to November 2 in Tokyo. NTN will begin selling this product in November through the NTN Technical Service Corporation, one of its subsidiaries.

Features

- Automatic system for adjusting compression conditions

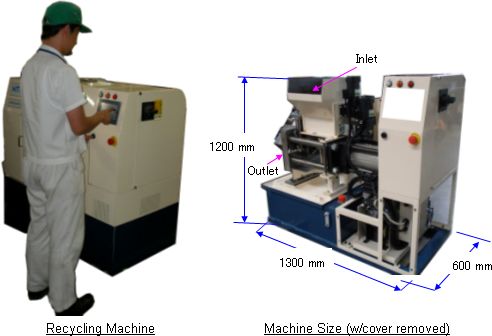

⇒ Automated setting to optimize compression conditions (pressure and speed) determined by the water content in grinding sludge - Small Installation Area

⇒ Width of 1300 mm, depth of 600 mm and installation area of 0.80 m2 (40% of conventional PRG-I machine) - Improved Ergonomics

⇒- Total height is 1,200 mm for easier loading of product

- Touch panel system enhances machine control

- Real-time remote monitoring system enables prompt response to emergencies

- Saves Energy

⇒ New control system has inverter driven hydraulic pump that only runs when cylinder operates (power consumption reduced by 14%)

Specifications

- Disposition capacity = Max. 13 kg/h (5 tons/month)

- Compression capacity = Max. 300 kN

- Briquette diameter = φ40 mm

- Approx. machine dimension = Height 1,200 mm × Width 1,300 mm × Depth 600 mm

Inquiries about this release

Product photo

Grinding Sludge Recycling System