Development of a Light and High Efficiency Drive Shaft Exclusively for Rear Wheel Drive CarsMay 27, 2010

[Responding to the need improved fuel economy and ride quality for luxury cars]

NTN Corporation (hereafter NTN) has developed a light and high efficiency drive shaft designed exclusively for rear wheel drive cars. In recent times, government regulations in various markets are mandating increased average fuel efficiency across corporate vehicle fleets. Therefore, it is essential to decrease the mass of drive train components so as to benefit increased fuel efficiency across all vehicle segments, including luxury cars. While optimizing designs to meet this requirement, NTN is also able to reduce backlash in the rotational direction of drive shaft to enhance driving feel and operation.

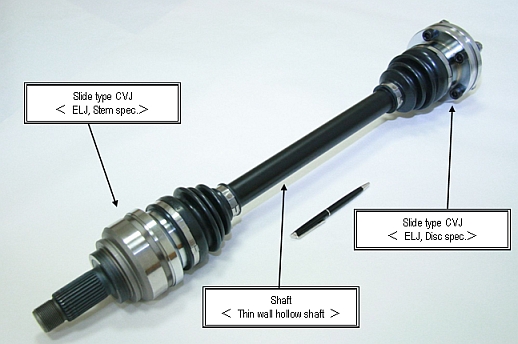

The drive shaft developed this time is composed of two pieces of newly developed slide type, cross-grooved, constant velocity joints (hereafter new product) and a hollow shaft inter-connecting the two joints (Refer to the appearance photo of the next page).

Compared to conventional cross-grooved constant velocity joints (hereafter conventional product), NTN reduced the outer ring outer diameter of the new product by using smaller balls and lowered the part mass using a hollow inter-connecting shaft. Meanwhile, the new product has the same durability as the conventional product by increasing number of inserted balls from six to ten.

Compared to conventional product, the new product is designed to achieve less rolling element sliding by creating a smaller inclination angle between the ball groove against the axial line. Design optimization also led to higher efficiency (reduction of torque loss) and to the reduction of backlash in the rotational direction.

In response to market needs, NTN will be presenting this drive shaft to the luxury car markets in Japan, Europe and elsewhere to satisfy mounting demand for low fuel consumption.

This new product was exhibited at “Automotive Engineering Exposition” (Booth No. 224) held in the Pacifico Yokohama for May 19 to 21.

Features

<In comparison with conventional product>

| (1) Light weight |

Mass reduced by 16% ← Outer ring O.D. reduced using smaller balls + Use of thin wall hollow shaft |

|---|---|

| (2) High efficiency |

Rate of torque loss lowered by 40% ← Slide of rolling elements reduced by making inclination angle of ball groove smaller |

Inquiries about this release

Product appearance photo