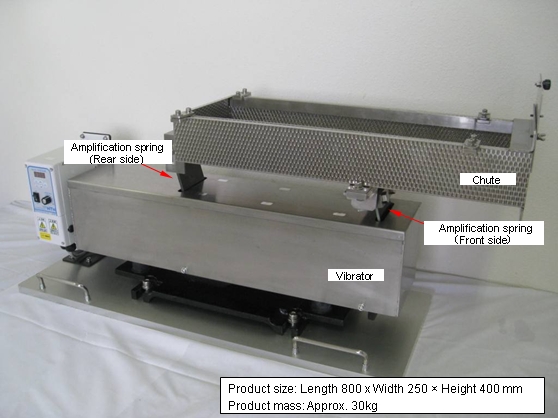

Development of “Food Feeding High Speed Linear Feeder”January 6, 2010

NTN Corporation (hereafter NTN) has developed a “Food Feeding High Speed Linear Feeder”. This feeder uses an “amplification spring mechanism,“ providing an increased vibration amplitude in comparison to the conventional linear feeder. It also enables the feeding of a variety of kinds of foods and vibration-absorbable parts, while contributing to energy savings.

Linear feeder is a machine designed to feed and supply parts (foods) by vibrating the equipment (main body). The conventional linear feeder has also been used for feeding various kinds of foods. However, the feeding of soft and vibration absorbable foods, such as pasted food or minced / steamed fish was not possible.

In response to such an application, NTN worked to develop a linear feeder with an operational capability in high amplitude vibration. The maximum vibrational amplitude of NTN's conventional linear feeder (part no.: K-S30) was about 2mm. By contrast, feeding soft and vibration-absorbable foods, such as pasted food, requires a vibrational amplitude of about 3-4 mm. Generally, a high strength leaf spring and a strong magnet are necessary to ensure a large vibration amplitude, thus requiring increased power consumption. The newly developed product uses an “amplification spring mechanism” and enables operation with high vibrational amplitude. In addition, by using the same mechanism that is used in the conventional linear feeder, the same power consumption as that of the conventional feeder is maintained, contributing to energy savings. High strength CFRP* material is used for the amplification spring.

* CFRP : Carbon-Fiber Reinforced Plastic

This new product was exhibited at “Parts Feeder Exhibition 2009 (hosted by Japan Industrial Newspaper Company)” held at the Tokyo Big Sight from November 25 to 28, 2009.

Features

| (1) High vibrational amplitude |

By use of the amplification spring mechanism, conventional vibration amplitude is further increased (by max. 2 times) and foods, etc., are fed at high speed. |

|---|---|

| (2) Power savings |

By using the amplification spring mechanism, a magnet with high magnetism is no longer needed and the same power consumption as that of conventional product is maintained. |

| (3) Stable feeding |

By changing the strength of the amplification springs of the front and rear sides, uneven feeding is curved over an entire chute and stable feeding becomes possible. |

Inquiries about this release

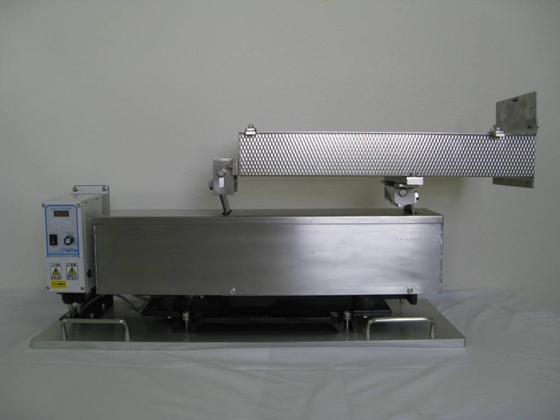

Photos