December 24, 2009

Development of Machine Tool Ball Screw Support Unit “BSTU Series”

[Achieving world's highest load capacity, long life & low torque]

NTN Corporation (hereafter NTN) has developed and commercialized a double row angular contact ball bearing “BSTU series” for machine tool ball screw support units.

NTN has been marketing the “Ball screw support single row thrust angular contact ball bearing (BST series)” as a machine tool precision bearing (ALTAGE series). This time NTN has developed and commercialized a high load capacity double row angular contact ball bearing unit, and added it to the ULTAGE series.

The single row BST series has been applied (in the form of multiple row assembly of single row angular contact ball bearings) primarily by Asian manufacturers, and the product developed this time is intended to respond to standard specifications of European manufacturers. In Europe, double row angular contact ball bearing units with housing-fixing holes on outer rings are generally used.

This bearing has the world's highest load capacity as a ball screw support bearing, and attains low torque (starting torque = 1/2 of other makes) and high dust proofing performance through use of a new type of seal. NTN names the bearing “BSTU (Ball screw Support angular contact Thrust ball bearing Unit) series”. In addition to single body type, duplex type is also available in the BSTU series.

NTN will market this product globally, as well as in the European market.

[ Features ]

| 1. |

World's highest load capacity: High load capacity, longer life and high rigidity were attained through the increase of the ball diameter and use of the highest number of balls. |

| 2. |

Use of a new low torque and high dust proof seal is standard: Low torque and high dust proof performance were simultaneously achieved by use of new seal lip configuration. In addition, seals are fitted on both sides as a standard specification. Accordingly, at the time of bearing assembly, the processes of washing, degreasing, and greasing are not required. |

| 3. |

Maintenance free: Greasing during service is no longer needed because the bearing is filled with long life grease in advance. |

| 4. |

Easy installation: Fitting into housing was made easier by providing fixing bolt hole on outer ring. |

[ Application ]

Machine tool ball screw support (Machining center, Complex machine tool etc.)

[ Product photos ]

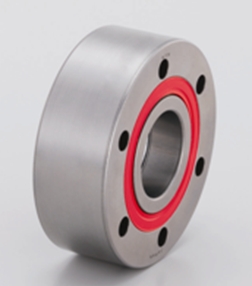

BSTU3080 Single body type |

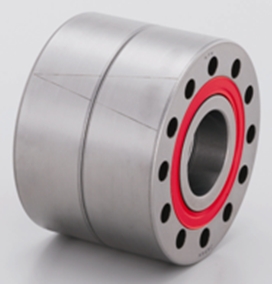

BSTU3080 Duplex type |

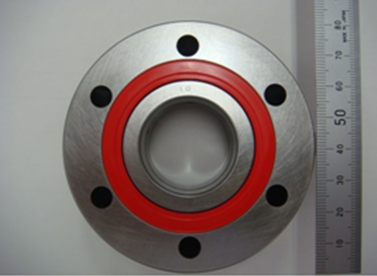

BSTU3080 Dimension |

|